1.Logo/Printing 3M Tape test

1.Logo/Printing 3M Tape test

2.Basic function check (Functions on product specification work )

3.Battery capacity test

4.Charging test

5.Discharge test

6.Bluetooth connection

7.Bluetooth connection Distance 10 meters test

8.Phone connection function test

9.Siri function test

10.Battery voltage check

11.Inner check

Tent Quality Control Inspection

Some common factors for tent quality control:

Appearance

Quantity check

Measurement(weight & size)

Basic function test

Card buckle check

Fabric GSM check

Sewing firmness check

Spraying firmness test

Zipper smoothness check

3M tape test for Logo

Barcode scanning

Carton dropping test

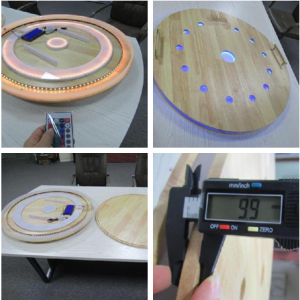

Party Rack Final Quality Inspection Service

1.Logo/Printing 3M Tape test

2.Assembled

3.Basic function check (Functions on product specification work )

4.Barcode Scan

5.Odor test

6.Pull Test

7.Measurement of product

8.Material check

9.Appearance

10.Completeness of the body

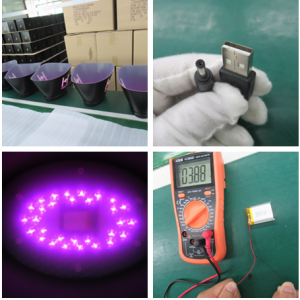

Ice Bucket Full Quality Check

1.Appearance

2.Quantity check

3.Carton dropping test

4.Material check

5.3M Tape test

6.Logo/Printing 3M Tape test

7.Rubbing test

8.Charging test

9.Discharge test

10.Internal check

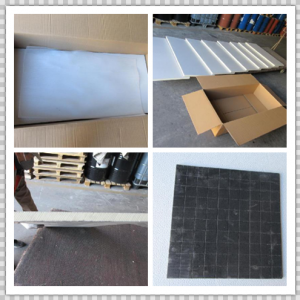

Panel pre-shipment inspection

Some common factors for panel quality control:

Appearance

Quantity check

Measurement(weight & size & thickness)

Basic function check

Barcode scan

3M tape test for Logo

LED outdoor sign QC inspection

Some common factors for LED outdoor sign quality control:

Appearance

Quantity check

Measurement(weight & size & thickness)

Aging test

Basic function check

Power test

Sensor test

Waterproof test

3M tape test for Logo

Plank Final inspection

1.Appearance

1.Appearance

2.Quantity check

3.Pull test

4.Material check

5.3M Tape test

6.Rubbing test

7.Pull test

8.Assembly test

Key Checking Point of Faucet

Some common factors for faucet quality control:

Appearance

Quantity check

Measurement(weight & size)

Basic function check

Assembly test

Leakage test

Barcode scan

3M tape test for Logo

Key Checking Point of Earring

Some common factors for Earring quality control:

Appearance

Quantity check

Measurement(weight & size)

Basic function check

Barcode scan

3M tape test for Logo

Key Checking Point of Waste Processor

Some common factors for Waste Processor quality control:

Appearance

Quantity check

Measurement(weight & size)

Hi-pot test

Grounding test

Basic function check

Current leakage test

Input power test

Motor rotate speed test

Noise test

Assembly test

Drop test

Remote control function test

Rubbish process test

Power cord pull test

Barcode scan

3M tape test for Logo