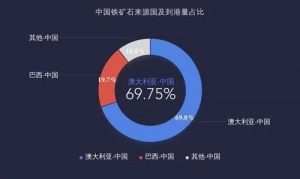

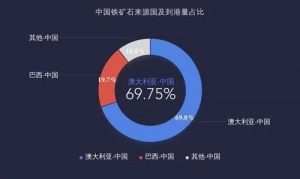

We used to joke that our country was an infrastructure freak, building railroads, Bridges, buildings, etc., all of which were built on steel, and high demand for steel meant high demand for iron ore. However, it is regrettable that China is not a country rich in iron ore reserves, although China’s iron ore reserves ranked fourth in the world, but because China has a large population, so the average number of iron ore per person is not much. In addition, China’s iron ore quality is relatively poor, and most of the 300, 400 meters deep underground, so that the mining cost is high. Because of this, China is heavily dependent on imported iron ore, which accounts for about 90% of its output, 69% of which is from Australia and 19.7% from Brazil. Due to rely heavily on iron ore, and rely heavily on Australian iron ore, lead to the way foreign break through for iron ore chock the lifeblood of our country iron and steel industry (of course, the abroad is also a kind of loss, after all, they couldn’t find another like internationally in countries with high demand for iron ore in China). In this case, why don’t we vigorously develop waste steel recycling, but to import iron ore from abroad?

Why not recycle old steel?

In fact, our country has always been recycling old steel, but our country began to vigorously develop infrastructure at the end of last century, so far only 20-30 years of history. Because of its short history, much of the steel is still in use and cannot be recycled. Secondly, China’s development speed is very fast, the demand for steel is also very large, and the waste steel is far from meeting our demand for steel, so we still need to make steel from iron ore. In addition, the supply of scrap steel is unstable, and the price fluctuates greatly in the short term, so that enterprises can not control the cost, so they prefer to import iron ore from abroad. More importantly, the quality of waste steel in the market is different. After recycling waste steel from the hands of residents, manual sorting and transportation are needed, which increases the operating cost, so that the selling price of waste steel has no advantage compared with iron ore.

Moreover, in order to ensure the efficiency of large steel plants, their machinery and equipment are made to adapt to the calcination process of iron ore. And the recycling of waste steel needs matching equipment, which increases the cost input of enterprises. From the above factors, enterprises are more inclined to use iron ore, rather than the use of scrap steel. But in order to protect the environment, there are also some enterprises will use recycled old steel, but the output of recycled old steel is not high.

Why import iron ore?

As we know, our country has vast territory and abundant resources, and many important mineral resources can be found in our country, so why do we need to import iron ore from abroad?

This is actually because of the high cost of iron ore in China. First of all, because most of the iron ore in China is lean ore, that is to say, the iron content in iron ore is not high, so it is difficult to extract iron. In addition, most of the iron ore in China is a composite ore with multiple elements, so that the quality of iron ore is not the same. However, Australia is not only rich in mining, but also mostly open-pit mining, with lower mining costs. Even if sold at a lower price, it can still earn profits, so it is more competitive in the international market. Moreover, it is difficult to form scale effect because of the small reserves of iron ore in China. However, the ore in Australia is not only of high quality, but also of large reserves, which is easy to form scale effect and further reduce the mining cost. In addition, China’s iron ore is mainly transported by railway and land, and the transportation cost is high. And in Australia, it’s mostly by sea, so shipping costs are low, so even importing iron ore is still much cheaper than mining it ourselves. However, it is precisely because China is heavily dependent on iron ore, which leads to a disadvantageous position in the negotiations with Australian iron ore. It is difficult to control the pricing power, so that China can only import at a high price.

The solutions are as follows: developing alternatives to iron ore; Improve the utilization efficiency of waste steel; Importing iron ore from more countries to spread the risk; Investment in foreign iron ore enterprises, but these methods can not be implemented for the time being, can only hope that we can find a better solution later.

Conclusion

The reason why it is difficult to use waste steel in China is that:

Scrap steel production is small, difficult to meet the needs of enterprises.

Waste steel transportation, sorting and other links are too many, the cost is high, when the cost is not low.

Modern enterprise equipment is mostly built to adapt to iron ore, it is difficult to digest waste steel.

The reason why we need to import iron ore from abroad at a high price is really out of necessity. After all, China’s iron ore reserves are not high, and the quality is not high, so the cost of using domestic iron ore is high, so we can only import iron ore from abroad.

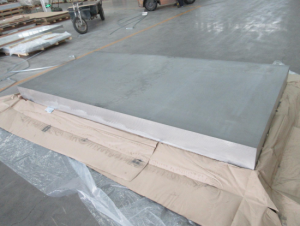

1.Appearance

1.Appearance