Granite Inspection Procedure & Key Points

This document outlines the standard procedure and critical focus areas for inspecting granite slabs and tiles before shipment or upon receipt.

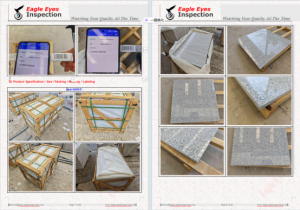

I.?Pre-Inspection Preparation

Document Review:

Purchase Order (PO): Verify quantity, dimensions, thickness, finish, and product name.

Quarry Block Report: Confirm the origin of the stone batch.

Packing List: Cross-check against the actual shipment.

Tools & Environment:

Tools: Measuring tape/caliper, straightedge, square, moisture meter, digital colorimeter (if color matching is critical), UV lamp (for resin detection), and a bright light source.

Environment: Inspection must be conducted in a well-lit area, preferably under natural daylight or bright, neutral white light to accurately assess color and finish.

II. Inspection Procedure & Key Points

The inspection should be systematic, covering visual, dimensional, and physical characteristics.

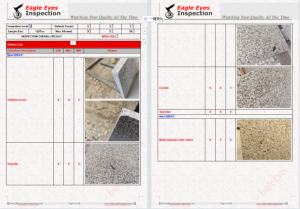

A. Visual Inspection (Surface Quality)

Color & Pattern Consistency:

Focus: Compare slabs/tiles from the same batch. There should be no drastic color variation from the approved sample.

Key Point: Natural variation is expected, but it should be within an acceptable range as per the project requirements.

Finishing Quality:

Polished: Must have a uniform, high-gloss mirror finish without hazy or dull areas.

Honed: Should have a smooth, satin-uniform matte finish.

Flamed/Bush-Hammered: Texture should be consistent across the entire surface.

Surface Defects:

Cracks & Fissures: Distinguish between superficial fissures (natural, usually acceptable) and structural cracks (deep, often unacceptable).

Chips & Pits: Check for small missing pieces on the surface, especially on edges and corners.

Stains: Look for oil, rust, or chemical stains that cannot be removed.

Discoloration: Check for blotches or areas that are significantly darker/lighter.

Veining & Markings:

Focus: Ensure the natural veining is as expected. Check for ugly or concentrated spots of minerals that affect aesthetics.

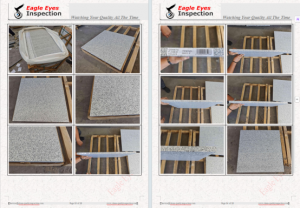

B. Structural & Dimensional Inspection

Thickness:

Focus: Measure thickness at multiple points (center and all four corners) using a caliper.

Key Point: Thickness must be consistent and within the tolerance specified (e.g., +/- 1mm for 2cm slab).

Dimensions:

Focus: For tiles, check length, width, and diagonal dimensions.

Key Point: Ensure consistency to avoid lippage (uneven edges) during installation.

Squareness & Flatness:

Squareness: Use a carpenter’s square to check if corners are 90 degrees.

Flatness: Place a long straightedge on the surface. Check for any gaps indicating warpage or bowing.

C. Resin & Filling Inspection

Purpose: Most granites are resin-treated to fill minor pits and fissures and enhance the polish.

Inspection:

Visual: Look for areas where the resin has a different gloss, color, or transparency than the natural stone. It should be invisible.

UV Light: Use an ultraviolet lamp. Resin-filled areas will often fluoresce differently than the natural stone, revealing the extent and quality of the repair.

Key Point: Excessive or poorly matched resin is a major defect.

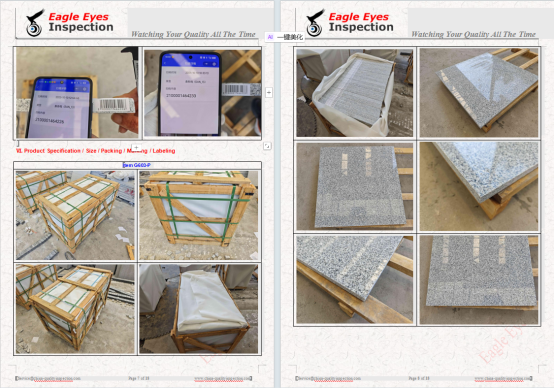

D. Physical Condition & Packing

Edges & Corners:

Focus: Inspect for chipping or damage on all edges and corners, which are highly vulnerable.

Moisture Content:

Focus: Use a moisture meter. High moisture content can lead to efflorescence (white salt deposits) after installation.

Key Point: Slabs should be dry, especially if they are resin-treated.

Packing:

Focus: Check if slabs/tiles are properly packed with sturdy crates, adequate separators (e.g., foam or cardboard between slabs), and well-secured to prevent movement and damage during transit.

III. Defect Classification & Reporting

Major Defect: Structural cracks, deep stains, excessive warpage, or any flaw that makes the piece unusable for its intended purpose. Result: REJECT the piece.

Minor Defect: Small, superficial pits, minor color variation, or small edge chips that can be repaired or are acceptable for the project. Result: Document and negotiate a discount or repair.

AQL (Acceptable Quality Level): For large shipments, use a statistical sampling plan (like AQL) to determine how many pieces to inspect and the maximum number of allowable defects.

Final Report: The inspection report should include photos of all defects, measurements, and a clear summary of accepted, rejected, and questionable pieces