1.Appearance

2.Quantity check

3.Carton drop test

4.Material check

5.Sealing Check

6.Logo/Printing 3M Tape test

7.Rubbing test

8.Odor smell check

9.Basic function check

10.Flatness check

1.Appearance

2.Quantity check

3.Carton drop test

4.Material check

5.Sealing Check

6.Logo/Printing 3M Tape test

7.Rubbing test

8.Odor smell check

9.Basic function check

10.Flatness check

1.Appearance

2.Quantity check

3.Carton dropping test

4.Material check

5.3M Tape test

6.Logo/Printing 3M Tape test

7.Rubbing test

8.Odor test

9.Logo/Printing 3M Tape test

10Basic function check

11.Stability test

1. Inspection company services (inspection services)

In the process of product development and production, independent third-party inspections that can be trusted are required to conduct cargo inspections to ensure that customers’ product quality standards are met at every stage of production.

Benefits of different types of inspection services as below:

Inspection before shipment

When the production of the order is 80% complete, the inspector will go to the factory to inspect and use the industry standard process to comprehensively inspect and test your product, including process, packaging, steamed bread, etc., to ensure that it meets the agreed specifications and industry standards. . Having a professional and qualified inspection service can better ensure that the product meets the customer’s specifications and ensure that the goods will not cause errors and cause risks.

Inspection during production

This service is very suitable for the strict requirements of large-scale shipments, continuous production lines, and fashion shipments. If bad results are found during pre-production inspections, then the production batches are checked and the products on the production lines are checked for possible defects. , Usually when 10-15% of the product is complete. In-production inspections can determine if there are any deviations, make recommendations for corrective actions, and re-examine any defects during the prenatal inspection to confirm that they have been corrected. Why do customers need to check during production? Finding defects early and taking action early can save customers time and money!

Pre-production inspection

After you have selected a supplier, you must complete the pre-production inspection before mass production begins. The main purpose of the pre-production inspection is to check whether your supplier understands your requirements and the specifications of your order, and prepares for it.

The main content of pre-production inspection:

Check the preparation of production materials

Check whether the factory understands your order requirements

Check factory production schedule

Check the production line of the factory

Loading supervision and inspection

Some inspection processes performed during all loading operations, including the packaging process performed at the manufacturer’s plant or warehouse, the packing process before shipment, checking whether the goods meet all requirements, checking the appearance of the package, the number and size of the boxes Meet contract standards and transportation standards, check the protection of transportation, and also check the cleanliness of transportation, such as cargo holds, railway wagons, ship decks, and more.

2. Why do we need factory audit services?

Factory audit services can help you ensure that your potential existing suppliers provide high-quality products, operate efficiently and support continuous improvement.

Factory audit services

In today’s highly competitive consumer market, buyers need a supplier base to work with them to meet all aspects of production, from design and quality to product life cycle time and delivery requirements. However, how do you effectively select new partners? How do you monitor the progress of existing suppliers? How do you effectively work with suppliers to maintain a focus on quality and time?

The factory evaluation audits the factory’s production capacity and performance to prove that the factory is capable of producing products that meet quality. The key criteria for the evaluation are policies, procedures, and records that demonstrate the factory’s ability to provide consistent quality management over time At a specific time or only for certain products.

The core areas and processes of factory assessment design include:

Quality management system

Good production practice

Factory environmental standards

Product control

Process control

3.Why does your supply chain in China and Asia need QC inspection?

Find quality issues early so you don’t have to deal with defects after the product has landed.

Performing quality checks at all stages-not just pre-shipment checks-will help companies monitor their products and processes and make important decisions to improve their current systems.

Reduce your return rate and risk of product failure. Handling customer complaints takes up a lot of company resources. It’s also tedious for employees.

Keep suppliers alert-get better quality products. In a way, it’s a way to collect data to increase efficiency. Being able to spot problems and weaknesses will enable them to correct these errors and respond accordingly.

The speed of your supply chain. Effective quality control before shipping will help reduce marketing costs. It will help you shorten lead times and facilitate timely delivery of products to recipients.

Some common factors for Magnet Pad quality control:

Appearance

Quantity check

Measurement(weight & size & thickness)

Basic function check

3M tape test for Logo

Barcode scanning

Carton dropping test

1.Appearance

1.Appearance

2.Quantity check

3.Smell test

4.Function test

5.Material check

6.Pull test

7.Logo/Printing 3M Tape test

8.Sewing fastness test

9.Zipper fatigue test

10.Load test

First of all, we need to understand the important components of the product routine inspection process, such as the appearance of the product, the conformity of the quantity, Product compliance check, the packing method, the inspection of the box mark and the field test. Corresponding inspection steps should be matched according to different products. “Mask” is composed of fabric and process with textile properties, so it follows the particularity of textile products to verify the standardization of “mask”.

1) Product appearance inspection: check whether the outer and inner layers of the “mask” are stained, dirty or damaged by naked eye and touch. Check the earring part of the mask and see if the joint is firm. Whether the nose clip of the mask is completely wrapped by non-woven cloth, check the tightness of the nose clip. In addition, the mask should be fully extended to check whether the edges of the mask are properly pressed, and the shape of the folds should be checked after the mask is extended. Check that masks, earrings and nose clips are the correct size.

2) Product quantity conformity check: Check whether the actual completed product quantity is consistent with the PO quantity in the order.

3) Product compliance checks: A. product model is consistent with the customer ordered, whether products are for civilian or medical. If for medical, packaging requirements whether reach the standard of surgical masks, tensile test whether can meet the requirements of relevant mask of standard; General civil masks 10 n/s test is to be fulfilled within 10 Newton (for 10 seconds) according to the standard (GB/T32610-2016), surgical masks to meet 50 n/s test namely (within 50 Newton for 10 seconds). B. Stratify the mask and check whether the mask is composed of three layers: inner, middle and outer. The fabric composition should include non-woven cloth and molten spray material. C. Whether the material of the product is consistent with the customer’s requirements. For the comparison test of the material, color and gram weight respectively with the customer’s requirements or reference samples, polypropylene is the typical material for the manufacture of surgical masks.

4) Functional inspection: A. Place the mask on a piece of white paper and conduct a waterproof test. If the white paper is wet, the waterproof function of the mask does not meet the standard. B. Use an open flame to ignite the edge of the mask to test its flame retardation. A mask meeting the standard will not burn, and vice versa. C. Odor test and skin allergy test to check for pungent odor and ensure skin comfort. D. Electrostatic adsorption test: the masks with meltblown fabric inside will attract small pieces of paper.

5) Weighing check: Check the weight of the mask cut and divided into layers. As the mask is a special textile material, it must be weighed with a professional gram-plate. A sampler is used to cut the facemask of the facemask divided into layers.

Factory Audits are performed according to the standard of ISO9000 or customized requirements.It helps the clients to know if the factory has the ability to complete their order as required.

For a standard Factory Audit, it mainly covers the below fields:

Factory Profile

It is the general information about the factory, such as the factory’s foundation date, the work floor area, the main customers, the number of employees, the organization and the product main process etc.

Factory Facilities and Machinery Conditions

It gives some basic information about the machines and facilities, such as the number of machines, the machine type, the maintenance condition and the housekeeping situation etc.

Electric Power Supply and Delivery / Loading Condition

To check if the public power supply is stable, if the factory has enough back-up power generators when needed and the time from the factory to the airport or port etc.

Production Capacity

To check if the factory’s production capacity in terms of number of machines, workers and warehouse etc. can meet the order volume.

Quality Assurance system

To check the factory’s quality control process in procurement, equipment calibration, in-coming material, manufacturing, final products and customer’s complaint handling areas.

Hygiene and Security

To check if the employees are in a good and safe working condition.

Some common factors for beauty blender quality control:

Appearance

Quantity check

Measurement(weight & size)

Basic function check

Rub & 3M tape test for Logo

Barcode scanning

Pantone color check

Carton dropping test

Some common factors for chopping board quality control:

Appearance

Quantity check

Measurement(weight & size)

Basic function test

Humidity Test

3M tape test for Logo

Barcode scanning

Carton dropping test

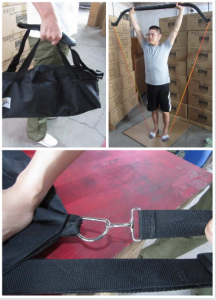

Some common factors for resistance band quality control:

Appearance

Quantity check

Measurement(weight & size)

Basic function check

Rub & 3M tape test for Logo

Barcode scanning

Pantone color check

Color fastness test

Odor test

Carton dropping test