1.Carton dropping test

1.Carton dropping test

2.Barcode scanning test

3.Humidity check

4.Odor check

5.Canister capacity check

6.Adhesion check for painting

7.Burn function check

8.Color shading check

1.Carton dropping test

1.Carton dropping test

2.Barcode scanning test

3.Humidity check

4.Odor check

5.Canister capacity check

6.Adhesion check for painting

7.Burn function check

8.Color shading check

1.Carton drop test

1.Carton drop test

2.Function check

3.Barcode Scan

4.Paper GSM check

5.Smell check

1.Bar code test

2.Function test

3.Rubbing test

4.Adhesive test

5.Dynamic Strength Test

6.Max weight test

7.Fatigue test

8.Carton drop test

9.Product drop test

10.Pull test

1.Sewing strength pull test

1.Sewing strength pull test

2.Fabric GSM check

3.Color Fastness Check

4.Bar code scanning

5.Washing test

1.Basic function check

(functions on product specification work )

2.Loading test

3.3M TAPE test

4.Rub off test

5.Drop test

Some common factors for Quilt and Cover quality check:

1,Logo/Printing 3M Tape test

2,Basic function check?

3,Barcode Scan

4,Seam Strength Test

5,Rub test/Pilling Test with cloth

6,Smell test

7,Color contrast test

8,GSM check

9,Needle detection test

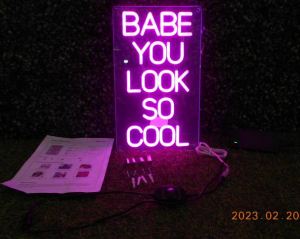

1.Barcode scan test

1.Barcode scan test

2.3M tape test

3.Rub test

4.Aging test

5.Assembly test

6.Dimmer function test

7.Dimmer knob fatigue test

8.Power-on lighting test

Some common factors for Dog Launcher quality control:

Appearance

Quantity check

Measurement(weight & size)

Rubbing test

Basic function check

Smell test

Inner check

Barcode scan

Carton drop test

3M tape test for Logo

Some common factors for Electric Wire Rope Hoist quality control:

Appearance

Quantity check

Measurement(weight & size)

Barcode scan

Drop test

3M tape test for Logo

1.Hi-pot test

2.Ground continuity test

3.Fatigue test

4.Internal workmanship check

5.Speed test

6.Barcode Scan test

7.Power consumption test

8.Stability test

9.Adhesion test

10.Remote test

11.Product endurance test for about 5 hour