Clothes-garment-jacket AQL qc inspection

I. Overview of AQL inspection

AQL: is the abbreviation of average quality level, that is, the average quality level, which is a parameter of inspection, not a standard.

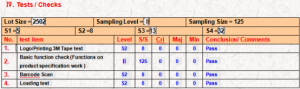

During the inspection, the quantity of samples and the quantity of qualified and unqualified products are determined according to the batch range, inspection level, and AQL value.The garment quality inspection adopts a sampling scheme, the qualified quality level (AQL) of the garment batch is 2.5, the inspection level is the general inspection level, and the inspection strictness is the normal inspection.

Clothing inspection items

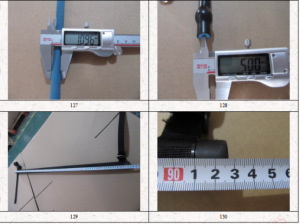

Size and shape check: size and shape table.

Key size points — collar length (flat knit) collar width, collar circumference (knitted) collar spread (knitted) chest circumference, sleeve opening (long sleeve), sleeve length (to sleeve edge), back length (flat knit) center measurement (knitted)/shoulder top measurement pants, waist, lower hip circumference, front wave, back wave, zipper open, bottom mouth, inner circumference/back length of pants other (single piece/set), Vertical look, plus the top of the clothes, pants size.

Non-critical size points — non-critical size points, such as minimum width, shoulder height, chest circumference, sleeve seam, collar width, sleeve piece, front and back wave, waist circumference, lower hip circumference, flat pocket position, opening.

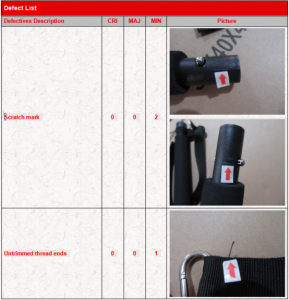

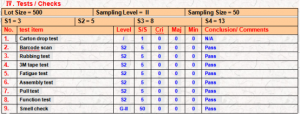

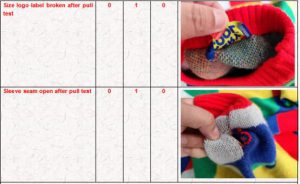

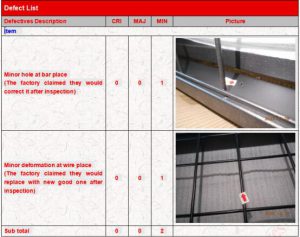

Defects inspection: The appearance, shape, dressing and found defects of all clothes are categorized separately.

II.Scoring standard

AQL is the maximum number of defects in 100 pieces of clothing. It is considered that the average processing level of this clothing batch (piece) is satisfactory according to the number of qualified Ac(piece) after sampling inspection. If the number Re(pieces) is reached, the average processing level of this garment batch (pieces) is considered to be unacceptable. The criteria for scoring during the inspection process are as follows:

General defects — starting from the organization specifications and quality standards of the order, it will not achieve the performance of the product, affecting the appearance and internal appearance of the garment. Non-critical size points, general defects. Rework can eliminate the impact of defects on the appearance and interior of the garment. If the garment factory is repaired on the basis of this defect, it must do 100% re-inspection before shipment, and the inspector can limit the specific specifications, colors, sizes, etc. Three general defects are converted to one serious defect.

Serious defects — affecting the appearance and shape of the garment. When consumers buy the clothes, they will not buy the clothes again if they see such defects, or such defects will cause them to wear the clothes for the first time or after washing, consumers will return the clothes. Such as damage, stains, color strips, holes, key size points? Severe defects. If a serious defect is found, the next item is judged to be substandard or unacceptable.

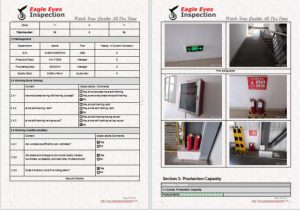

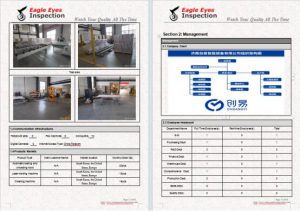

III.Pre-production inspection. This is a pre-production inspection to check specific specifications or general requirements of the company.

The first meeting is very important in order to establish a quality assurance system with the factory, so that each department has the latest information (check). The focus of this inspection is: Dressing packaging label printing flower shape, color standards, re-check the specification sheet and all relevant information, before cutting to clarify its content.

During production, check the finished products after the first piece or batch of finished products, check the contents: size, color, design, materials, organization structure, handwork, trademarks, price tags and packaging of finished products. If there is any problem, the information should be fed back to cutting and sewing, asking them to re-check and correct.

Finished product inspection Generally at least 80% of the product has been completed, and the packaging is ready for export, and the sample must be taken out of the finished garment. If the inspection fails, the factory shall take 100% responsibility, conduct 100% inspection of the goods in place, and report the final rework status to the buyer. All expenses incurred in connection with the rework shall be borne by the factory. The final inspection report confirms :

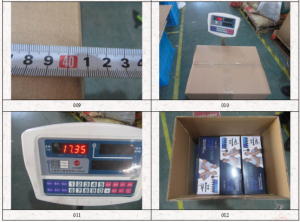

1. The box is accurate;

2. The gross weight and size of the carton;

3. Net weight of goods,

4. Final size, color matching.

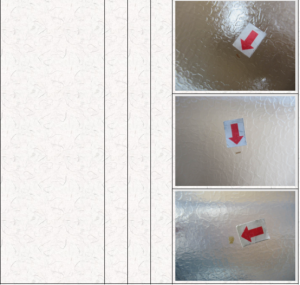

Needle inspection .Due to poor management in the production process, there are often broken needles (including stitches, pins, etc.) in quilting products such as clothing. In the 1980s, the frequent occurrence of consumer injury caused by broken needles in clothing prompted the government to enact consumer rights protection regulations in the form of legislation to strengthen the control of broken needles. According to regulations, if there is a broken needle in the production and distribution of products, its producers and sellers will be heavily punished, and compensation will be paid if the harm is caused to consumers. In order to avoid economic losses caused by broken needles, garment importers not only require manufacturers to inspect needles before the product leaves the factory, but also set up special inspection factories to engage in needle inspection. Hang or attach needle marks to products that pass the inspection needle.

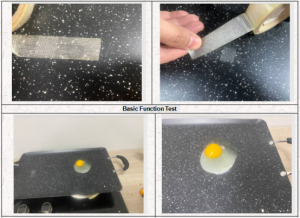

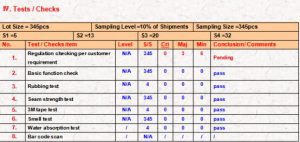

Clothing test and inspection

1. It needs to show that the cloth has been tested

2. Clothing test also describes the following practices

The inspector pulls out from the bulk goods .The clothes of the same quality sample group as the bulk goods are tested. The standard garment washing test method is used and tested by the factory itself.

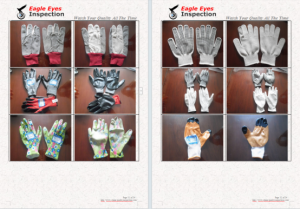

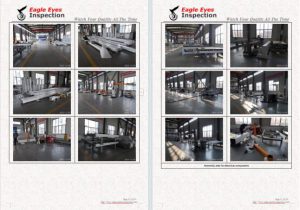

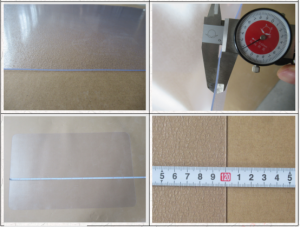

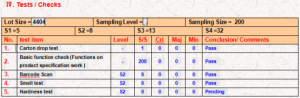

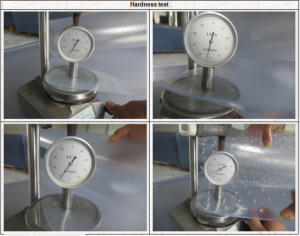

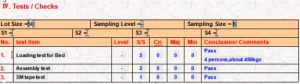

Product quality inspection;

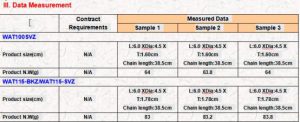

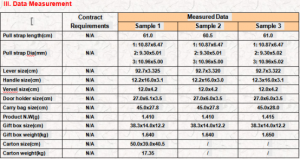

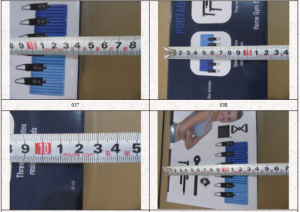

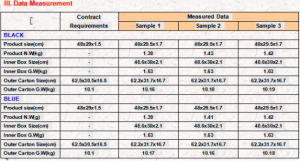

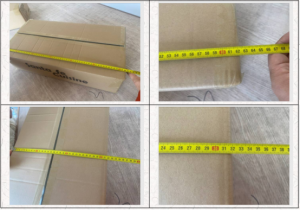

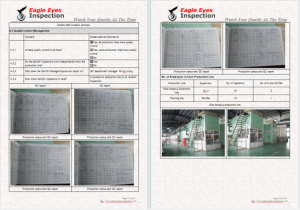

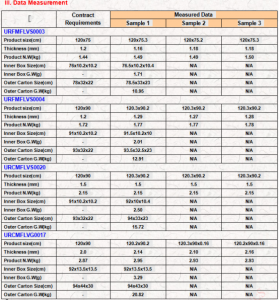

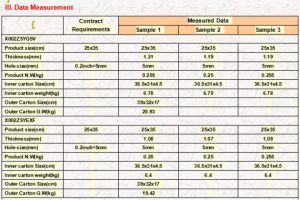

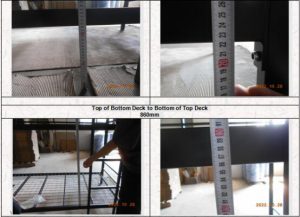

Product quality inspection; Measured data(Product size,Outer Carton size)

Measured data(Product size,Outer Carton size)

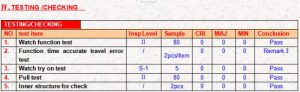

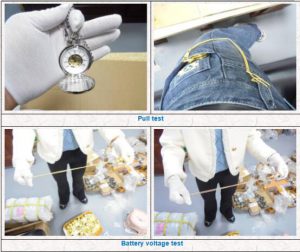

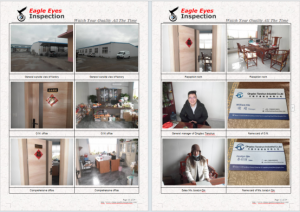

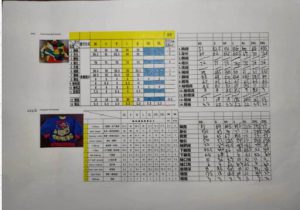

Inspection Report

Inspection Report

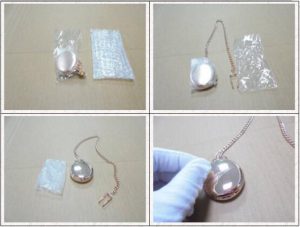

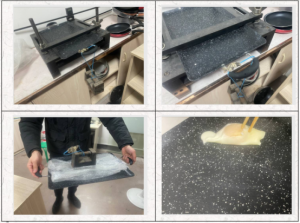

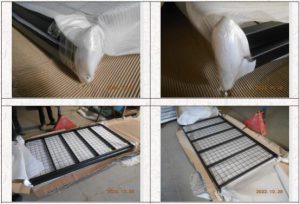

Packing check(color box,out cartons.)

Packing check(color box,out cartons.)

Product quality inspection;

Product quality inspection;

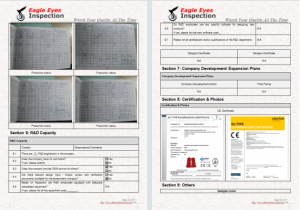

Measured data(Product size,Outer Carton size)

Measured data(Product size,Outer Carton size)

Product quality inspection;

Product quality inspection; Measured data(Product size,Outer Carton size)

Measured data(Product size,Outer Carton size)

Packing check(color box,out cartons.)

Packing check(color box,out cartons.) Inspection Report

Inspection Report

Product quality inspection;

Product quality inspection;

Measured data(Product size,Outer Carton size)

Measured data(Product size,Outer Carton size)