Floor acceptance criteria

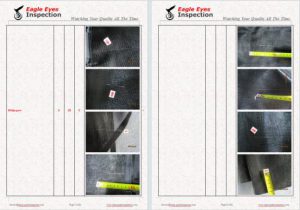

1, See if the color of the floor is consistent. If the color difference is too large, directly affect the beauty, you can find the swap. Whether the color is consistent, there is almost no color difference, it depends on the pattern of the floor surface no the same. If the pattern is similar, it may be a process wood floor, rather than the so-called.

The flooring of the precious wood species. Now some flooring material suppliers, the use of general wood material .The floor, but on the surface of a layer of rare wood species of wood veneer to shoddy, said to be used to moisture-proof, in fact,for fear of being seen that the pattern on the back does not match the pattern on the front.

2, See whether the floor has a sound, acceptance on the floor. Walk up and down, step more, so especially near the wall and door parts should pay more attention to acceptance, found that there is a sound part, to repeat walking.

Determine the exact location of the sound and mark it. In this case, you can ask for removal and resurfacing. There are the part of the sound is that the construction personnel in the construction process, the operation is not standardized and the use of materials is not qualified. The non-standard operation is mainly reflected in the unstable fixing of the keel; The unqualified materials are mainly reflected in.The keel has not been dried. Some decoration construction units use undried keel construction on the surface.

There are drying marks. It’s not dry. A keel with a high moisture content, formed during the natural drying of wood the volume will shrink, causing loosening.

3. Check whether the floor is deformed and warped. The method of acceptance is to use a 2-meter long ruler and lean on it.On the floor, the flatness should not be greater than 3 mm. Take a few more measurements, if the pass rate is above 80%.It is regarded as qualified, otherwise, it is not qualified. Sometimes we find the floor partially arching: if it is a solid wood floor, which is because the floor is too tight or too dry (too low water content); if it’s laminate flooring. That means poor flooring. Therefore, the floor arch is a serious quality problem.

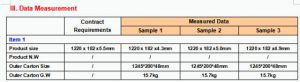

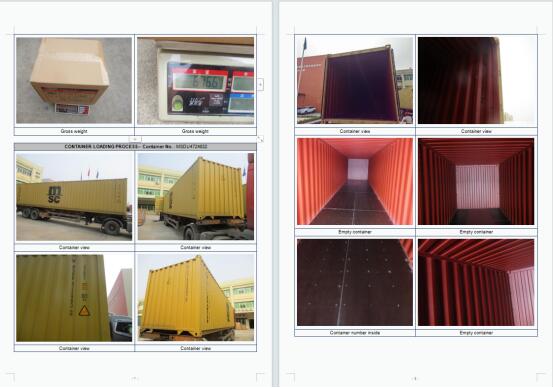

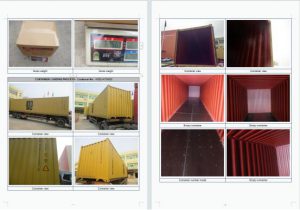

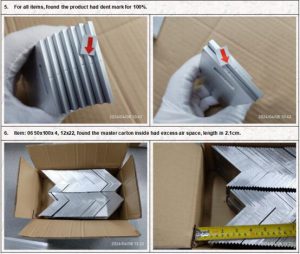

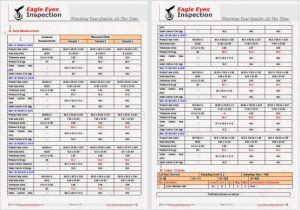

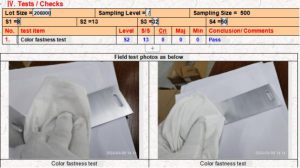

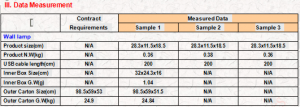

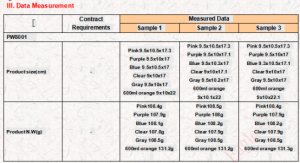

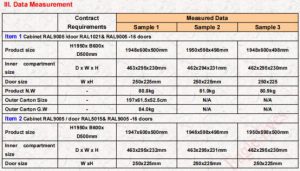

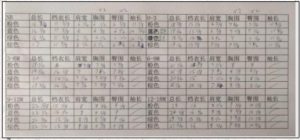

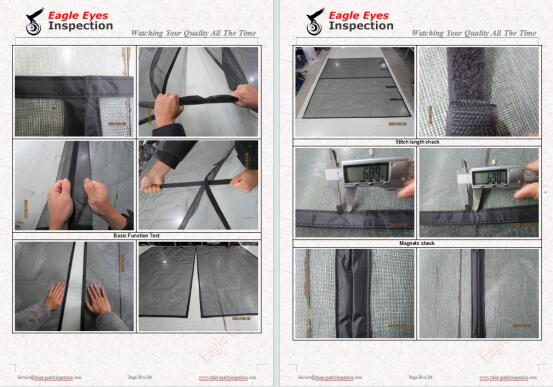

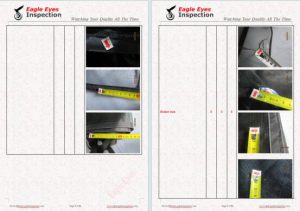

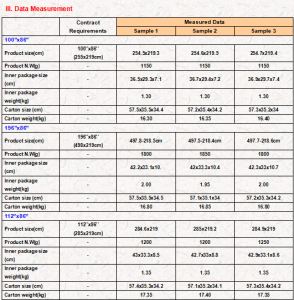

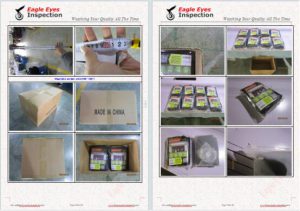

Measured data(Product size,Outer Carton size)

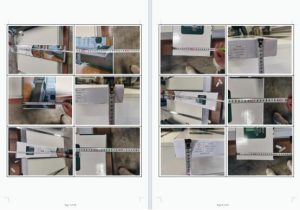

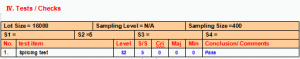

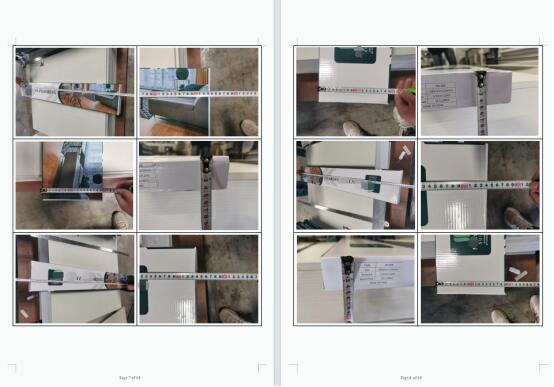

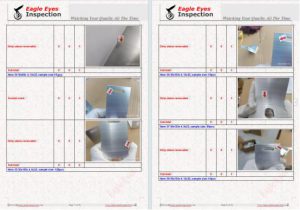

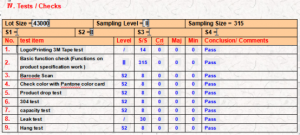

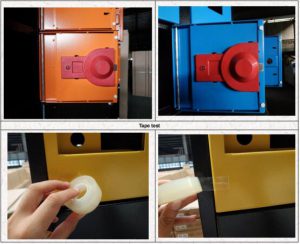

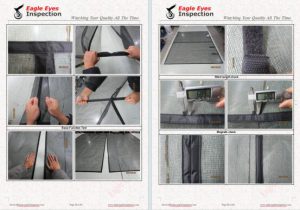

Special test for Wooden flooring

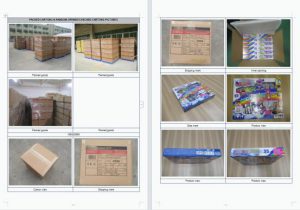

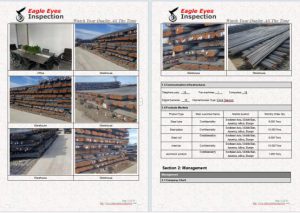

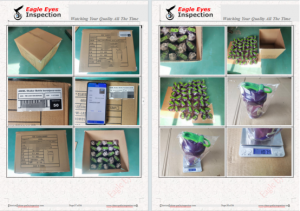

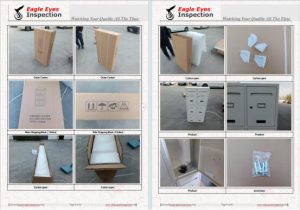

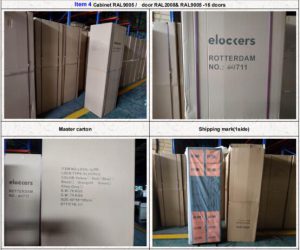

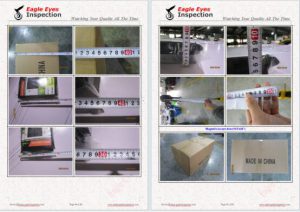

Packing check

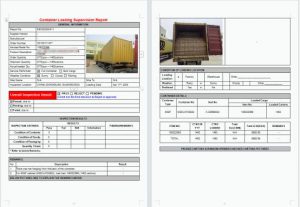

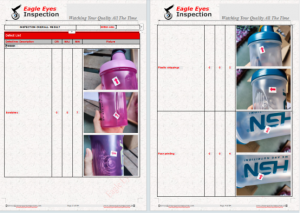

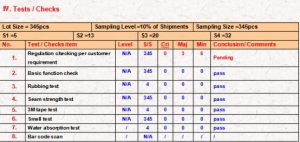

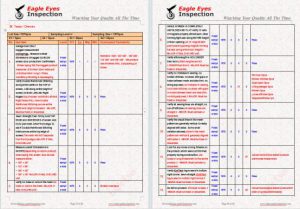

Inspection Report

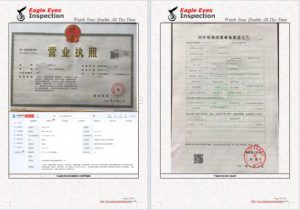

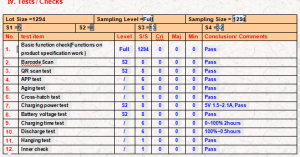

The report shows the situation at the inspection site. Check and verify that the goods meet the requirements of size, weight, packing and workmanship according to the information provided by customer. Work is good, function test is normal. After reading the report, customers can accurately judge whether the goods meet the requirements of the order.

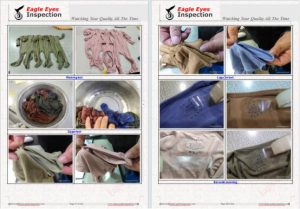

?Product quality inspection;

?Product quality inspection;

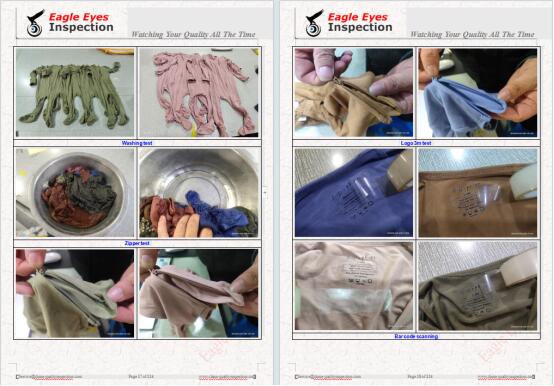

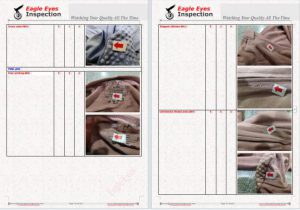

Clothing inspection standards

Clothing inspection standards

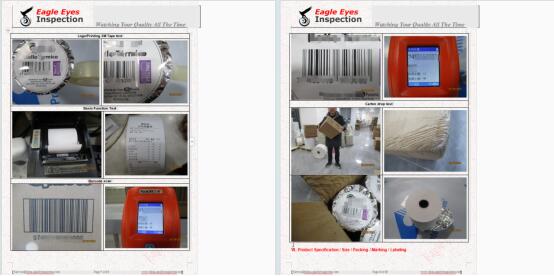

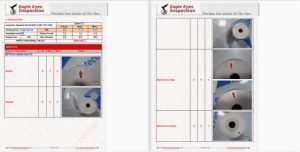

Measured data(Product size,Outer Carton size)

Measured data(Product size,Outer Carton size)

Packing check

Packing check Inspection Report

Inspection Report

Inspection Report

Inspection Report

Thermal paper is mostly used in commercial supermarkets, gas stations, transportation departments, advertising, tourist areas, enterprises and institutions, and these institutions have a wide range of demands for bills, bar codes, tickets, etc. In some large enterprise units, thermal paper is also one of the common materials for logistics procurement. Thermal paper is an indispensable special paper for modern information processing technology, which has the advantages of fast printing speed, compact and portable printing equipment, low printing noise, no need to change the ribbon, and high clarity for bar code recognition. The national standard for thermal paper is GB/T 28210-2011 “thermal paper”, but in recent years, the rapid development of the thermal paper market, many new products have been developed, GB/T 28210-2011 can not represent the current technical requirements, so many manufacturers in the purchase of thermal paper, will negotiate with the manufacturer to specify the relevant indicators.

Thermal paper is mostly used in commercial supermarkets, gas stations, transportation departments, advertising, tourist areas, enterprises and institutions, and these institutions have a wide range of demands for bills, bar codes, tickets, etc. In some large enterprise units, thermal paper is also one of the common materials for logistics procurement. Thermal paper is an indispensable special paper for modern information processing technology, which has the advantages of fast printing speed, compact and portable printing equipment, low printing noise, no need to change the ribbon, and high clarity for bar code recognition. The national standard for thermal paper is GB/T 28210-2011 “thermal paper”, but in recent years, the rapid development of the thermal paper market, many new products have been developed, GB/T 28210-2011 can not represent the current technical requirements, so many manufacturers in the purchase of thermal paper, will negotiate with the manufacturer to specify the relevant indicators.

Perform special tests on products according to the site conditions and equipment.

Perform special tests on products according to the site conditions and equipment.