1. Every product should be inspected carefully.

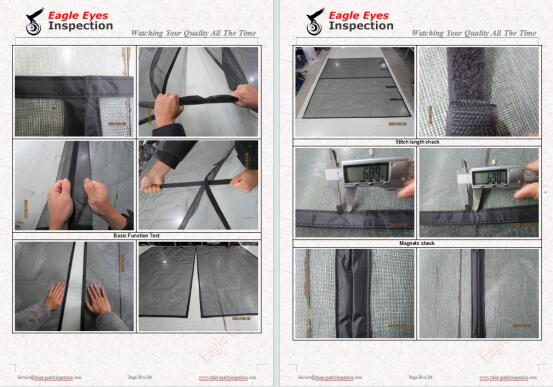

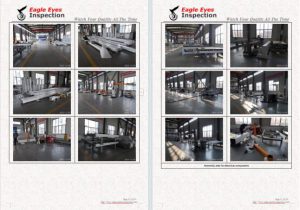

Test process requirements

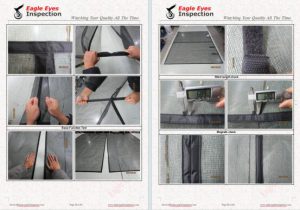

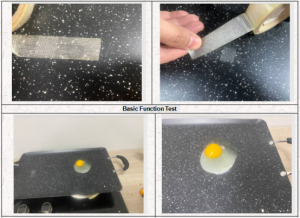

1. Open the product, check the quality test of the connecting car line around the product first.

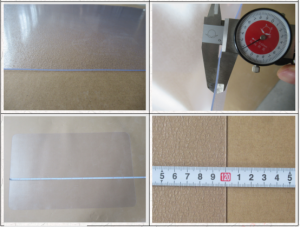

2. Check the quality of the screen.

3. Check the quality of each product’s small magnet and long magnet strip;

4. Make sure that the silk-screen LOGO in the lower right corner has no defects.

5. Turn over the product and check the quality, length and so on of the nylon tape line:

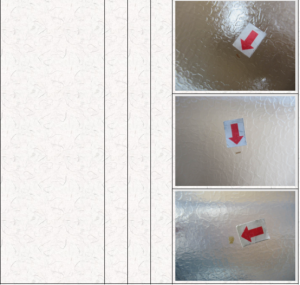

(1) Make sure that each magnet is attracted to the magnet on the other side. There was a product issue where two pairs of magnets repel each other (which doesn’t work), so each pair of magnets needs to be tested. Each pair of magnets needs to be tested to make sure that each pair attracts each other. (Note that the long magnet strip is not magnetic enough, it is defective, and it should be picked out).

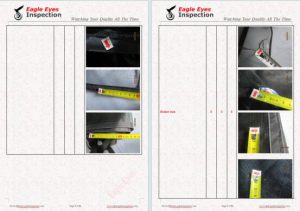

(2) Check whether the curtain mesh is torn, disconnected, holes, inconsistencies and other defects.

(3) Check the front and back edges of the curtain for any defects.

(4) Make sure that the silk screen LOGO in the lower right corner does not have any defects.

(5) Ensure that each product is equipped with pushpins and Velcro straps.

(6) Ensure that each product has inserted paper cards and bar codes.

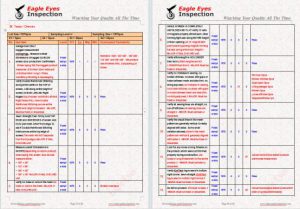

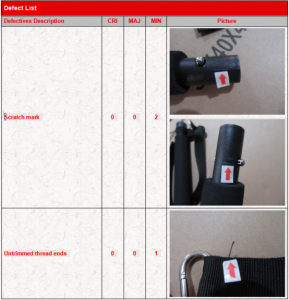

Check product workmanship according to customer requirements.Once an exception is found, the customer is notified immediately.

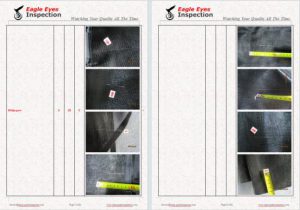

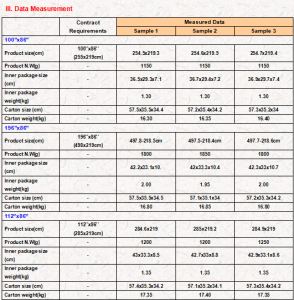

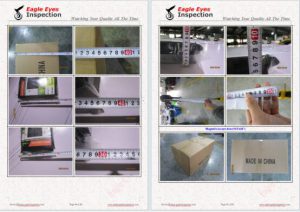

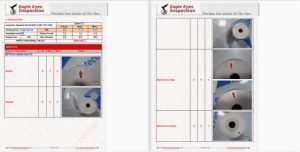

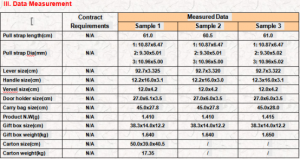

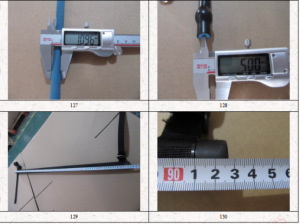

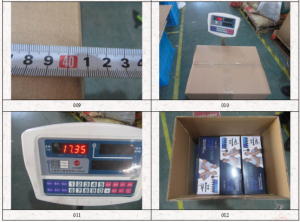

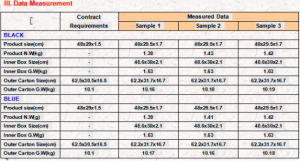

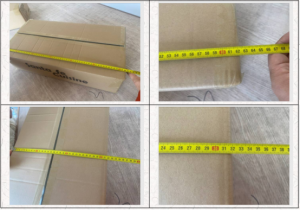

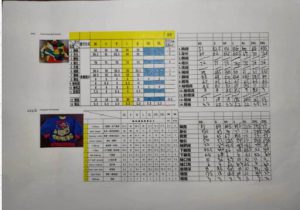

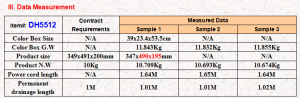

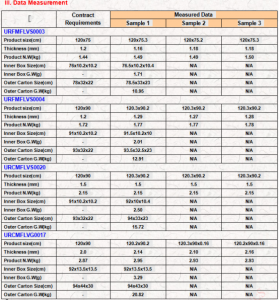

Measured data(Product size,Outer Carton size)

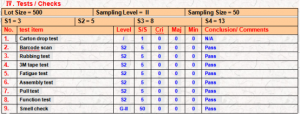

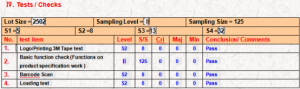

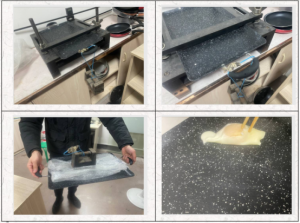

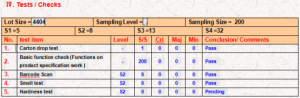

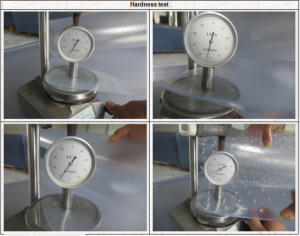

Special tests magnetic screen door

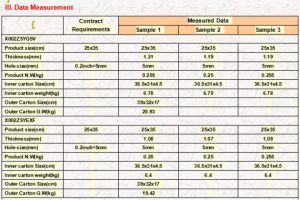

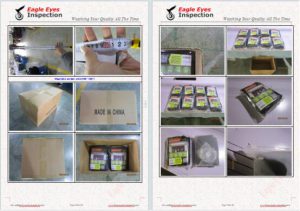

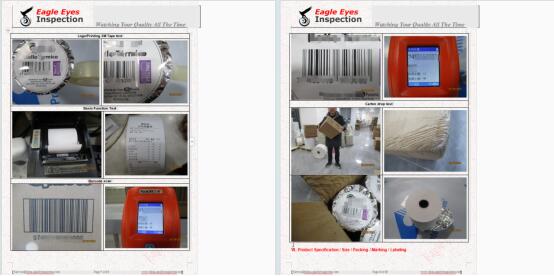

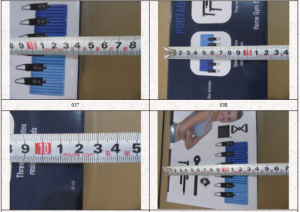

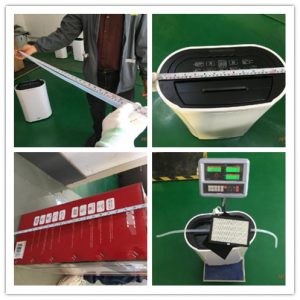

Packing check(color box,out cartons.)

Check whether the package meets customer requirements, determine the size and weight of the package, and check whether the package is suitable for product transportation. Inspection Report

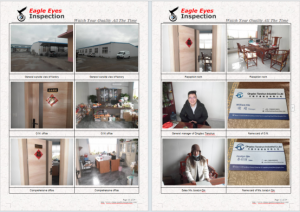

Inspection Report

Eagle eyes quality inspection company will provide inspection report within 24 hours after inspection.The inspection process is checking and verifying that the goods meet the requirements of size, weight, packing and workmanship according to the information provided by customer. Work is good, function test is normal. After reading the report, customers can accurately judge whether the goods meet the requirements of the order.

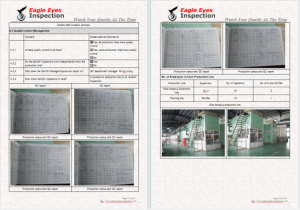

Thermal paper is mostly used in commercial supermarkets, gas stations, transportation departments, advertising, tourist areas, enterprises and institutions, and these institutions have a wide range of demands for bills, bar codes, tickets, etc. In some large enterprise units, thermal paper is also one of the common materials for logistics procurement. Thermal paper is an indispensable special paper for modern information processing technology, which has the advantages of fast printing speed, compact and portable printing equipment, low printing noise, no need to change the ribbon, and high clarity for bar code recognition. The national standard for thermal paper is GB/T 28210-2011 “thermal paper”, but in recent years, the rapid development of the thermal paper market, many new products have been developed, GB/T 28210-2011 can not represent the current technical requirements, so many manufacturers in the purchase of thermal paper, will negotiate with the manufacturer to specify the relevant indicators.

Thermal paper is mostly used in commercial supermarkets, gas stations, transportation departments, advertising, tourist areas, enterprises and institutions, and these institutions have a wide range of demands for bills, bar codes, tickets, etc. In some large enterprise units, thermal paper is also one of the common materials for logistics procurement. Thermal paper is an indispensable special paper for modern information processing technology, which has the advantages of fast printing speed, compact and portable printing equipment, low printing noise, no need to change the ribbon, and high clarity for bar code recognition. The national standard for thermal paper is GB/T 28210-2011 “thermal paper”, but in recent years, the rapid development of the thermal paper market, many new products have been developed, GB/T 28210-2011 can not represent the current technical requirements, so many manufacturers in the purchase of thermal paper, will negotiate with the manufacturer to specify the relevant indicators.

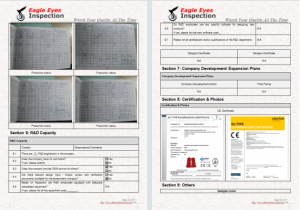

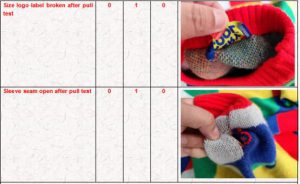

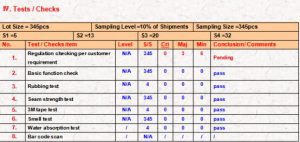

Perform special tests on products according to the site conditions and equipment.

Perform special tests on products according to the site conditions and equipment.

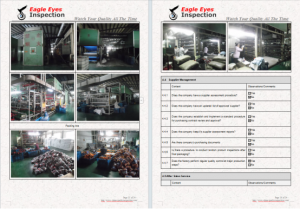

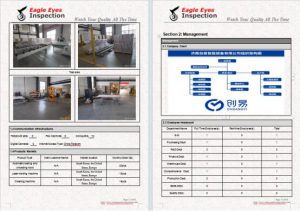

Product quality inspection;

Product quality inspection; Measured data(Product size,Outer Carton size)

Measured data(Product size,Outer Carton size)

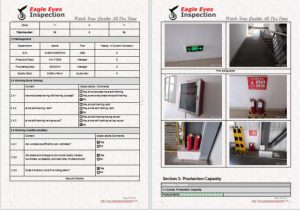

Inspection Report

Inspection Report

Packing check(color box,out cartons.)

Packing check(color box,out cartons.)

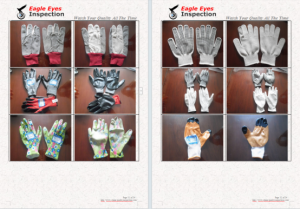

Product quality inspection;

Product quality inspection;

Measured data(Product size,Outer Carton size)

Measured data(Product size,Outer Carton size)

Special Special test for desumidificador products.

Special Special test for desumidificador products. Packing check(color box,out cartons.)

Packing check(color box,out cartons.)

Product quality inspection;

Product quality inspection; Measured data(Product size,Outer Carton size)

Measured data(Product size,Outer Carton size)

Packing check(color box,out cartons.)

Packing check(color box,out cartons.) Inspection Report

Inspection Report