Dongguan Wall lamp full check process;

Sampling Plan

1.Increase 100% appearance inspection positions in the production line;100% increase in alignment of weighing test accessories;Added tracking system label control;

2.MIL-STD-1O5E, S-2 for size and function check ,Level II (Normal) for appearance check, Acceptable Quality Level (AQL) = 0 of Critical – 2.5 Major and 4.0 Minor defect.

Viewing distance:30~35cm.

Viewing Time:5~10s.

Viewing Light:Cool fluorescent light with an intensity of 800~1100 lux.

Components can rotate horizontally and vertically.

Product quality inspection;

Including checking product workmanship, whether there are defects, color, specifications, size lights, whether they meet customer order requirements.

Surface Classification/Inspection Guidelines/Inspection Conditions/Defect Definitions/Acceptance Criteria/ Rejection Criteria/please refer to(Visual Quality Standard(synthetic rubber glue).

1.No scratches, breakage, leakage, scratch customer complaint history.

2.Refer to the specification, no more welding, virtual welding, less components.

3.No, lack of glue, deformation,wrinkle,poor viscosity.

4.Refer to the specifications, no deformation, multiple welding, virtual welding, less components.

5.Can not plug holes, lack of glue, deformation, external surface scratches and scratches, the lettering is required to be clear without mutilation, no fingerprints or other residue, color must match other components.

6.According to the specifications, the battery has no bulge, damage, wiring errors, and the battery jet code is clear and correct.

7.Check production date and specification, no damage, leakage.

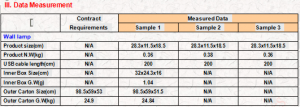

Size Check

Compare with specification.

Special test for wall lamp.

Packing check(color box,out cartons.)

Checking whether the package is fit for transport and meets customer requirements.

Need to scan the QR code to check, can not have the font incomplete, dirty, color difference and other defects, color stripe must align with color name printed on sticker.

1.Sticker color is consistent, no stains, no burrs, no damage, good adhesion.

2.Pay attention to matching, that is, the color discrimination sticker must be consistent with the actual color in the color box

3.Printing is clear and there is no deformity, and the box is not deformed, damaged or dirty and lower boxes are well matched,History of customer complaints of oil,breakage and wrinkles, box should not have any smudges or fingerprints anywhere.

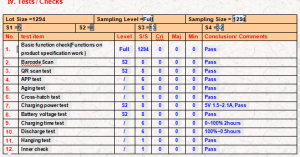

Inspection Report

The report shows the situation at the inspection site. Check and verify that the goods meet the requirements of size, weight, packing and workmanship according to the information provided by customer. Work is good, function test is normal. After reading the report, customers can accurately judge whether the goods meet the requirements of the order.