Some common factors for large mower quality control:

Appearance

Quantity check

Measurement(major size)

Basic function test(Functions on product specification work)

3M tape test for Logo

Barcode scanning

Some common factors for large mower quality control:

Appearance

Quantity check

Measurement(major size)

Basic function test(Functions on product specification work)

3M tape test for Logo

Barcode scanning

1. Visual inspection standards and inspection methods:

Surface grade

Class A surface: an external surface that can be viewed directly, such as the front and front sides of an electric water heater, hereinafter referred to as the A surface.

Class B surface: Inconspicuous external surfaces, such as the rear and rear surfaces of electric water heaters, hereinafter referred to as the B surface.

Class C surface; internal and external surfaces that are not easily visible, such as the floor surface of electric hot water, hereinafter referred to as the C surface.

Inspection environment

Luminosity: Normal light or 200-300LX (equivalent to a distance of 750mm for a 40W fluorescent lamp) The inspection surface of the product should be approximately 45 ° from the visual direction of the inspector.

The distance between the inspector’s visual direction and the surface of the product to be inspected is as follows:

A surface: 400MM B surface: 500MM C surface: 800MM

Degree of defect

Basic method for judging the degree of surface defects: under a standard inspection light source, the distance from the observation object is 400mm, and it should be at an angle of 45 degrees with the observation surface. Defects that are not visible at a glance are slight defects, visible at a glance, but not very obvious, are general defects. Visible and obvious defects are serious defects, and defects that are visible at a glance and seriously affect the appearance are fatal defects.

Defect sampling

Appearance is based on 1dm2. The 11.3cm circle selects the most defects.

Inspection methods and inspection standards

The A side should be smooth and flat with no obvious defects. No serious defects are allowed. No hand-painting is allowed to repair defects. Minor defects are allowed. No rough feeling or deformation can be felt by hand. The insignificant general defects have a diameter greater than 1mm is not allowed, less than 1mm is not allowed to exceed 10 points, and the concentration is not more than 3 / cm2. For non-orthographic planes, the standard can be appropriately relaxed. In the detection area, the diameter is less than 1mm. It is not allowed to exceed 15 points, and the concentration is not more than 3 / cm2.

The B surface should be smooth and smooth without obvious defects. No serious defects are allowed. Minor defects are allowed, and there is no rough feeling or severe deformation when touched by hand. Non-obvious general defects are not allowed in the detection area with a diameter greater than 1.2mm and less than 1.2. mm is not allowed to exceed 20 points, and the concentration is not to exceed 3 / cm2. For non-orthographic planes, the standard can be appropriately relaxed. In the detection area, the diameter is less than 1.2mm. It is not allowed to exceed 30 points, and the concentration is not more than 3 / cm2.

The C-plane allows the presence of general defects and serious defects that do not affect the appearance quality. The splicing gap is less than 1mm, which is acceptable. If it is more than 1mm but less than 1.5mm, it can be conceded according to the actual situation, and more than 1.5mm is unacceptable.

Signs, stickers, print inspections

Check the position of the signs, logos, stickers, and silk screens in accordance with the technical data to check that they are accurate, flat, and free from obvious skew. Failed.

Inlet and outlet pipe inspection

Check the water inlet and outlet pipes. The mouth of the pipe should be smooth and smooth, and the wire teeth should not be damaged and no obvious skew. Meet the requirements as qualified, otherwise as unqualified.

The exposed length of the inlet and outlet pipes should meet the design requirements. The length of the inlet and outlet water pipes shall meet the design requirements.

2. Structural parameter inspection standards and inspection methods

Dimension inspection

The overall dimensions of the product and the dimensions of the packaging box need to meet the dimensions and tolerance requirements of the design drawings, and those without tolerances are implemented as free tolerances.

Inspection with external dimensions

The size of the external fit must meet the size and tolerance requirements of the design drawing, and the free tolerance is implemented if no tolerance is marked. The outer cymbal fittings should be free from obvious skew.

Content volume inspection

Fill the container with water, put it on the weighing scale using a measuring bucket, and gradually pour the water from the product into the measuring bucket, and finally get the total water storage. The minimum content should meet the relevant capacity standards of the country or country of use, or the minimum allowable capacity requirements confirmed by the customer.

3. Inspection standards and inspection methods for hidden structural parameters

Quality inspection of slush layer

Use the light method to check the quality of the inner slush layer. The surface of the slush layer should be milky white, and there should be no burnt black, scars, cracks, whitening, puncture points, and debris in the slush layer. qualified.

Use light reflection perspective inspection or thickness gauge to check the thickness of the slush layer. The light reflection perspective inspection of the surface of the slush layer should show a uniform milky white, and there should be no gray-black shadows of the perspective substrate color (indicating that the slush layer is too thin). The minimum thickness measured by the thickness gauge should be more than 1.5mm, otherwise it is unqualified.

Foam layer thickness inspection

Using the thickness probe, take a point from the appearance and insert it into the shell to contact the liner, and measure the thickness of the foamed layer in each part. The thickness of the foamed layer should meet the design requirements. Those who meet the design requirements are qualified. If the area does not meet the design requirements but the area does not exceed 10%, and the error does not exceed 2mm, it may be conceded in consideration of the actual situation, otherwise it is unqualified.

Foam layer density test

Take a piece of 50X50X40 foam from both ends and the middle of the product, cut off the outer skin layer, and measure the density of the sample to calculate the average density. The average density should meet the designed density requirement, and the lowest density sample density must meet the minimum density requirement. Otherwise it is disqualified. The normal density requirement is 32 ~ 38KG / M3.

Tightness test

The products are connected into a system by using standard external connection accessories, and the normal work is performed under the use conditions. There must be no leakage at any connection parts, otherwise it is unqualified.

The inner tank is tested in accordance with the tightness test method, and there should be no leakage or leakage, otherwise it is unqualified.

4. Electrical safety performance inspection standards and inspection methods

4.1 Inspection of circuits and electrical components

Circuit and electrical device inspection

The electrical components are installed correctly, especially the switches, thermostats, and wiring cannot be reversed, incorrectly connected, or incorrectly connected. The installation of electrical components must be safe and reliable. Under the condition of limited pulling, pushing and pulling, the live parts of electrical components should not touch the metal parts such as the inner liner, screws, or heating parts. Cause the connection cable to be too tight.

There must be no foam, adhesive tape, screws, or metal parts spilling from the end cap.

The wiring and cable ties must be neat and reasonable. The connecting wires must not touch the sharp angles. The connecting pipes of the thermostat and temperature limiter probes must not be flattened.

Safety distance inspection of electrical components

Check that the distance between all exposed wires and terminals and metal parts should exceed the minimum distance required by safety regulations. All connecting wires and accessories should be firmly fixed. Under shaking and slight force, the distance from metal parts should still exceed the minimum safety distance. .

Ground wire safety connection check

The ground wire should be connected with standard yellow-green wires, and the connection fittings should be made of copper. The connection should be firm and reliable and should not be loose. Ground line signs, L, N and other signs must be correct, clear and durable;

Circuit connector safety test

Shake and pull the terminals and wires by hand, and the terminals, wires and screws should not loosen or fall off.

Functional check

Check whether the switch, indicator light and temperature control can work and indicate normally.

Maneuverability check

The knob must be flexible, smooth, and pointed correctly; the switches and keys are correct and reliable;

Accessories stability check

Use one hand to hold the case where the power cord enters, and hold the power cord with the other hand, and push it in and out twice. The power cord must not go in or out more than 2mm, and the power cord cannot be hung or broken. When it is pulled off, the screws holding the wire clamp must not be loose;

4.2 Ground resistance test

Ground resistance test

Insert the plug of the electric water heater into the socket of the ground resistance tester, and then clamp the ground wire clip to the water nozzle of the electric water heater or the hanger without spraying, start the ground resistance tester, and read the resistance value is not greater than 0.1 ohm (100 millimeters) (Europe) is qualified, otherwise it is disqualified.

The standard for grounding resistance is 25A 5S not more than 0.1 ohm (100 milliohms).

4.3 Withstand voltage test

Pressure test

Plug the electric water heater with a qualified grounding resistance into the socket of the withstand voltage tester, press the reset button of the leakage protection switch, adjust the switch and the thermostat to the on state, and start the withstand voltage tester without breakdown or flicker. To be qualified, breakdown, flashing, arc flash, and smoke were unqualified. The standard of withstand voltage is 1800VAC 5S without breakdown and flicker.

Note: During the pressure test, never touch the metal part of the water heater!

4.4 Leakage current test

Leakage current test

Press the reset button of the leakage protection switch of the electric water heater that has passed the withstand voltage test, adjust the switch and the thermostat to the on state, insert the plug of the electric water heater into the socket of the leakage current tester, and dial the L, N switch, read out the leakage current value in the L and N states, the leakage current per kilowatt is less than 0.75mA is qualified, otherwise it is unqualified.

The leakage current standard is 233VAC 5S leakage value <0.75mA / KW. Our company requires that the leakage current standard of each electric water heater is 233VAC 5S leakage value <0.75mA.

When testing the leakage current, check whether the switches and indicators can be lit and correct. Note: When testing the leakage current, the metal part of the water heater is live!

4.5 Power test

Power test

Insert the water heater plug that passed the leakage current test into the socket of the electrical parameter tester, turn on each switch one by one, and read out the corresponding power. The measured power is 0.9 ~ 1.05 times the rated power is qualified, otherwise it is unqualified.

4.6 Functional test

Heating test

Use heating according to the normal use state, check whether the temperature controller is normal, whether the switch is normal, whether the indicator light is normal, whether the inner tank water is normal heating, short the temperature controller, and check whether the temperature limiter can work normally. Everything is normal, otherwise it is unqualified.

5. Other inspection items

Stress safety test

Use an external air source to pressurize the tank filled with water to the take-off pressure of the safety valve, and check whether the safety valve takes off normally. When the pressure of the inner tank reaches the rated pressure of the safety valve, the normal pressure of the safety valve is qualified and abnormal. Failed.

Inject the liner into 90% water, then immerse the liner into the pool, increase the liner pressure to twice the use pressure, stabilize the pressure for 10 minutes, and observe whether the liner has changed. After the pressure was released from the liner, the shape was qualified if it did not change, and the shape appeared deformed and distorted, and even failed.

Liner fatigue test

Connect the bladder to the fatigue tester, and perform the pressure and pressure fatigue test. The frequency setting and frequency are performed according to the relevant product technical requirements. After the fatigue test is completed, the bladder is qualified if there is no obvious deformation and leakage. After the fatigue test is completed, In the case, obvious deformation and leakage of the inner liner were unacceptable.

Thermal insulation test

Warm the water in the product to the set temperature, turn off the heating power, place it naturally for 24 hours in a standard environment, measure the temperature to reduce the temperature difference, calculate the insulation performance parameters, and meet the relevant requirements of the country and the country of use as qualified, otherwise it is unqualified .

Thermal yield detection

The product is warmed up to the set maximum temperature. After reaching the temperature, it stays stable for 10 minutes. Measure the temperature of the water and then close the water inlet valve. Pour the hot water in the machine into the insulation bucket and mix it uniformly. Measure the temperature after mixing. And the temperature after mixing, calculate the heating rate of the liner water.

The product is heated from the set temperature to the set maximum temperature. After reaching the temperature, it stays stable for 10 minutes. Turn off the power, use a 45-degree thermostatic valve to drain water into the measuring barrel, and keep it until the outlet temperature is lower than 42 degrees. The amount of water and product content were used to calculate the thermal yield.

Suspension strength test

Fill the product with water and hang it on the suspension test wall, and then use the weighting block to double the weight of the product and suspend it for 4 hours. Check whether there is deformation in the hanger and the shell. Damage is qualified, otherwise it is unqualified.

Freezer test

Put the product in a -30 degree freezer, store it for 12 hours, take it out to restore the temperature at ambient temperature, and check whether the shell is deformed or broken. If there is no obvious deformation and crack, it is qualified, otherwise it is unqualified. Then test whether the product can still work normally, it can work normally and the electrical performance test is qualified, otherwise it is unqualified.

On market, there are so many kinds of masks, how do we distinguish them and how to choose?

There are two main categories: one is medical masks, one is civilian masks. Medical surgical mask, medical protective mask, N95, FFP2 can be used for protection in medical institutions, KN95 can not be used in medical institutions,? the general public can choose by themselves.What are the differences?

1. Medical: disposable surgical mask (medical nursing mask)

Disposable surgical masks, medical care, general standards: YY0969, usually cannot guarantee the filterability of pathogenic microorganisms, dust. It is? commonly used in conventional nursing care in the hospital, main effect is barrier between medical staff and patients daily cross contamination, no particular high demand. If used by the general public, that is to stop bad breath, the actual effect of protection is not very ideal.

2. Medical: medical surgical mask: yy0469-2011

Medical surgical mask must refer to the medical standard yy0469-2011 for production. If the enterprise sets its own enterprise standard to meet or even higher than the requirements of YY0469, it can also be printed on the mask packaging (therefore, it is not necessary to have YY0469 to be qualified, specific or to see the name of the mask and enterprise standard to identify); Surgical masks are mainly used for invasive operations such as surgery and catheterization in hospitals.

YY0469 has bacteria filtration performance requirements to the surgical masks, general filtration efficiency of non oily grains should reach more than 30%, filtering efficiency to achieve more than 95% of bacteria (note, here is not the meaning of N95, don’t be confused with medical respirator), in addition, medical surgical masks have requirement for synthetic blood penetrating (can be as simple as anti permeability) in production. The masks are generally divided into three layers: the internal water absorbing layer, middle filter layer, waterproof layer outside, each layer has a special role.

3. Medical: medical protective mask

Medical protective mask, next is disposable medical nursing mask, also known as medical protective mask, in line with gb19083-2003 standard, the important technical indicators include non-oily particle filtration efficiency and airflow resistance. For diameter (0.24 ± 0.06), the filtration efficiency of sodium oxide aerosol of m is not less than 95%, that is, N95 and above. Inspiratory resistance should not exceed 343.2 pa.

4. Civil use: KN mask: gb2626-2006/2019

Kn represents non oil particles, and KP represents oil and non oil particles. Kn is a respirator for the prevention of non oil particles (dust, smoke, microorganism: virus, pathogen) specified in Chinese standard gb2626-2006. In the national standard, the protection level is divided into Kn90, kn95 and kn100, kp90, kp95 and kp100. Kn refers to the prevention of non oil particles, and KP refers to the prevention of oil particles + non oil particles. The latter value represents the protection rate for ultrafine particles. Kn100 respirator and kp100 respirator are more than 99.97% for the protection efficiency of ultrafine particles. Therefore, kp100 mask and kn100 mask with higher protection level in the national standard can provide better protection effect than N95 mask.

See here, don’t know if you have found a problem, just the front, have to tell everyone about medical surgical masks (YY0469-2011) for non-oily filterability of particulate matter for 30% or more, the less than 95% or higher requirement in KN95 mask a lot, so a lot of people naturally think that KN type mask, especially the type KN95 masks, definitely better than the effect of medical surgical masks! Is that absolute?

Surgical masks have impermeable requirements, generally divided into three layers, the outermost layer for the waterproof layer, the most important reason to use masks in the medical environment is to isolate bacteria, and bacteria once attached to the surface of the mask, it is very easy to follow the moist mask directly into the mask, so, impermeable is very important!

And throughout the whole GB2626, there is no standard requirements for KN mask waterproof, not only KN mask, KP mask is not, that is to say, meet all the standards of GB2626 qualified masks, there is no anti-penetration requirements. At this point, KN masks are not as good as surgical masks!

FAQ 1: Is a breathing valve good or bad?

Because of wearing a mask of doctors and patients, all can’t promise you must be healthy, don’t (incubation period with infectious) with the virus, and masks airflow with exhalation valve is a one-way only protection, is not good to cut off the route of transmission, from the outbreak control perspective, the two-way protection is the right way, so don’t recommend this type of face mask.

FAQ 2: About the safety mask standard: gb19083-2010 and GB2626 which is good?

Misunderstanding: China’s GB19083 standard does not have “N95”, but the use of “level 1”, “level 2” and “level 3” to express the filter efficiency level, generally level 1 can meet the “N95/KN95” requirements. That is to say, as long as any “medical respirator” that conforms to GB19083 standard, the filtration efficiency of N95 and KN95 has been achieved absolutely.

Difference: GB19083 is the highest standard of medical execution, this is the standard of medical execution, this kind of mask you will find that there is no breathing valve, and are used in the medical scene, of course, if you buy it can also be outside civilian use.

GB2626 is usually used for civilian masks, mainly used as some protection such as painting, welding, industrial and haze and other non-medical scenarios of protection, such as the most common 3M brand KN95 masks is this type!

In addition, like the medical surgical mask of yy0469-2011, GB19083 also puts forward the requirements of “synthetic blood penetration”, and there is also a parameter requirement of “surface wetting resistance”, which makes clear the protective effect of the medical protective mask on blood and fluid, which is not in GB2626 (KN type). See the difference? There is no anti – flying liquid spillage for civil use.

EN 14683

This standard is intended to help facilitate the choice of surgical face masks in the European Market by standardizing the information and performance data required for the masks.

There are three test methods used to classify surgical masks:

1.Bacterial Filtration Efficiency in vitro (BFE) (ASTM F2101-07)

Test is used to determine the amount of infective agent that is retained by the surgical facemask, which is directly related to the amount of bacteria released through the mask into the air of the surgical theatre.

To test, a controlled flow of air containing an aerosol with a controlled concentration of Staphylococcus aureas is driven through a sample of the surgical mask containing all layers. The average size of the aerosol droplets is around 3.0 Micron. The number of bacteria that passes the sample is compared to the number that passes without the mask sample.

A higher BFE percentage indicates a better protection level for the patient against infective agents from the OR staff.

Classification:

BFE => 95% TYPE I

BFE => 98% TYPE II

A different BFE test called the “Modified Green & Vesley” or BFE in vivo has been used frequently in the past. This test method always provides extremely high values, but does not really differentiate between different quality surgical facemasks. The BFE in vivo test method is therefore not part of the new EU standard.

2.Breathing Resistance (Delta P)

Test is used to determine the resistance airflow of the facemask.

To test, a controlled flow of air is driven through a sample of the surgical mask containing all layers. The pressure before and after the sample is measured; the difference in pressure is divided by the surface (in cm2) of the sample.

A lower breathing resistance indicates a better comfort level for the user. It means the mask feels cooler and easier to breath through, and that the mask will maintain its shape in a better way as there is less pressure on the material. There will be less unfiltered air escaping around the mask.

Classification:

TYPE I & II (non splash resistant) = < 3.0 mmH2O/cm2

TYPE IR & IIR (splash resistant) = < 5.0 mmH2O/cm2

The breathing resistance is always measured per square centimeter of material. One way to increase comfort is to have a low breathing resistance value per cm2, the other to enlarge the surface of the facemask and thereby the total area available for ventilation.

3.Splash Resistance (ASTM F1862-07)

Test is used to determine the resistance penetration of potentially contaminated fluid splashes.

To test, a precisely determined quantity of specially prepared artificial blood is sprayed at a controlled pressure against a sample of the mask. Frequently these tests are done at pressures of 80, 120 and 160 mmHg. A visible inspection on the backside of the sample indicates if there is a fluid strike-through (red color) or not. The test is repeated 32 times at each pressure, and if three or less masks show a strike through, the product is considered splash resistant at that pressure.

A higher splash resistance means the mask will protect the user in a better way against splashes of potentially contaminated fluid during a surgical procedure.

Classification:

TYPE I & TYPE II not applicable

TYPE IR & TYPE IIR minimum 120 mmHg

120 mmHg is a minimum value. It corresponds to the average systolic arterial blood pressure, and intends to protect against ruptures in small arteries causing small sprays of blood. Some products off protection even in excess of the 120 mmHg.

Minimum Performance Requirements According to the New Facemask Standard EN14683

EU Standard Class

Bacterial Filtration Efficiency

Breathing Resistance (mmH2O/cm2)

Splash Resistance (mmHg)

I 95% < 3.0 NA

IR 95% < 5.0 120

II 98% < 3.0 NA

IIR 98% < 5.0 120

Ladies backpack check points

1. Check whether the attachment is missing

2. Check whether the belt is firmly sewed

3. Check whether the fabric is damaged or drawn

4. Check whether the fabric has chromatic aberration

5. Check whether the clasp/zipper is easy to use

6. Check whether the tubular trim is too short

7. Check whether the stitch spacing is too close/too thin

8. Check whether the seam is neat

9. Check whether the Logo printing is good

10. Check whether the hem stitches are good

Ladies backpack test

1. Zipper fluent test: during the test, pull the zipper by hand to see whether the zipper is smooth in the process of pulling. Unzip the zipper and then pull it up.

2. Snap reliability test: during the test, use hand rebate to check whether the function of Snap is applicable.

3. (3 M coating adhered test) , where there is printed with 3 m tape tear at ten times back and forth, whether the printing is off.

4. Measurement: according to the size given by the customer, check whether the product size data meets the customer’s requirements.

5. Mildew and odor test: check whether the product has mildew and smell whether the product has pungent odor

1. What are the functions of the purchasing department?

The functions of the purchasing department include:

(1) Grasp the required purchasing information in a timely manner and maintain good internal communication.

(2) Investigate and master the supply channels of materials used in production, and find sources of material supply.

(3) Establish a supplier profile and contact the supplier to prevent alternative suppliers from being found in an emergency.

(4) Refer to the raw material market and ask the supplier to quote.

(5) Evaluate the supplier’s supply price, material quality, delivery time, etc., understand the market price trend of the company’s main materials, produce procurement documents, and purchase the required materials.

(6) Coordinate the delivery time of the supplier according to the purchase contract.

(7) Assist the quality department to check the quantity and quality of incoming materials.

(8) Assist the material control department to prevent and treat sluggish and waste materials.

2. What are the main functions and contents of the procurement quality assurance agreement?

(1) The role of quality assurance agreement:

A. Clearly put forward quality requirements for suppliers. The quality requirements and inspection, testing and sampling methods specified in the agreement shall be recognized and fully understood by both parties.

B. Cooperate with suppliers to ensure the quality of purchased products.

(2) Requirements of quality assurance agreement:

A. The quality assurance requirements should be recognized by both parties to prevent hidden dangers to future cooperation.

B. The quality assurance agreement shall specify the inspection methods and requirements.

C. The quality requirements put forward in the quality assurance agreement should take into account the aspects of cost and risk.

(3) The quality assurance requirements provided in the quality assurance agreement may include the following:

A. Product standards mutually recognized by both parties.

B. The supplier implements a quality management system, and the company’s third party evaluates the supplier’s quality system.

C. The company’s acceptance inspection method (including the determination of the acceptable level AQL)

D. Supplier submits inspection and test data records.

E. Complete inspection or sampling inspection and test by the supplier.

F. The procedures / specifications on which inspections or tests are based.

G. Equipment, tools and working conditions used, clarifying methods, equipment, conditions and personnel skills.

3. What are the ways to reduce procurement costs?

The main ways to reduce procurement costs are:

(1) Seek more suitable suppliers.

(2) Look for materials that are more likely to be replaced.

(3) Improve procurement technology, such as increasing the number of purchases.

(4) Improve the original design.

(5) Improve storage and transportation methods and reduce inventory.

(6) Standardize procurement.

4. What does the procurement process include?

(1) Develop and implement procedures to control the quality of procurement to ensure quality control of products supplied by suppliers.

(2) Ensure that suppliers accurately understand the requirements for purchasing products.

(3) Ensure purchases from qualified suppliers. Each supplier’s ability to provide qualified products should be reviewed.

(4) A clear quality assurance agreement should be reached with the supplier and a clear agreement on the verification method to ensure uniform verification results.

(5) A method for solving quality problems shall be developed with the supplier.

(6) The quality records related to the products received and the purchase quality control records shall be kept to facilitate timely resolution and handling of quality issues.

5. How should procurement be implemented?

Procurement consists of four links, and each link consists of several steps.

(1) Purchase plan

The purpose of the plan is to formulate a purchasing plan based on customer needs and production capacity, and make a comprehensive balance to ensure timely supply of materials, while reducing inventory and costs, and reducing urgent orders.

The main links are: assessing order demand, calculating order capacity, and formulating order plans.

(2) Supplier evaluation

The purpose of supplier evaluation is to meet the purchase quality, cost, supply, and service requirements.

The main links of supplier evaluation are: preparation of supplier evaluation, preliminary selection of suppliers, trial production, batch testing, and determination of supplier list.

(3) Purchase order

The purpose of sending orders is to provide qualified raw materials and parts for the production department, and at the same time to evaluate and feedback the performance of the supplier group.

The main links are: order preparation, supplier selection, contract signing, and contract execution tracking.

(4) Purchase management

The main purpose of procurement management is to correctly implement the procurement principles of the enterprise.

The main links are: document approval, including planning, evaluation report, order contract, payment review and approval.

6. How to prepare a purchase order plan?

(1) Understanding market demand

For any production enterprise to make a more accurate order plan, it must first be familiar with the market demand plan, formulate the production demand plan from the further decomposition of market demand, and then formulate quarterly and monthly plans based on the annual plan.

(2) Understanding production needs

A. In order to facilitate the understanding of production material requirements, purchasing planners must be familiar with the common knowledge of production planning processes.

B. MRP comes from: production plan, independent demand forecast, bill of materials file, inventory file.

(3) Prepare basic information of the order

The basic information of the order includes:

A. Vendor information of the order material

B. For materials with multiple suppliers at the same time, the proportion of each order allocated by each supplier is coordinated by the purchasing staff.

C. Order cycle. According to the material items required by the production, the order formulator will query the information system to understand the basic purchasing parameters of the material.

(4) Materials needed for order planning

The contents of the information required for the order plan include:

A. Material name, required quantity and arrival date.

B. Sometimes market demand plan, production plan, and order basic information are attached.

7. How is the BOM file generated?

(1) The bill of materials is the core document of the manufacturing enterprise. The purchasing department should determine the purchase plan according to the bill of materials, the production department should arrange the production according to the bill of materials, the finance department should calculate the product cost based on the bill of materials, and the planning department should determine the cost of the materials based on the bill of materials. Demand planning, other sales, storage and other departments need to use the bill of materials.

(2) The bill of materials contains information on all assemblies, parts and raw materials that make up the product, and provides product composition information for the preparation of the material requirements plan.

(3) The BOM of the enterprise should be stored, maintained, updated, and managed uniformly by a full-time department, and a BOM database should be established to ensure the accuracy, completeness, and generality of the BOM, improve the efficiency of querying, and avoid the use of BOM. The practice of each department’s storage,

(4) Formulation of parts list. The product designer extracts data from the product design drawing to generate a list of all parts and components of the final product, forming a product parts list.

8. How to prepare a purchase order?

(1) Material items familiar with demand order operations

There are many types of orders. Order personnel should first be familiar with the order plan, take the time to understand the material items, take the time to understand the technical information of materials, etc .: Direct procurement from abroad may get better quality and lower prices, but at the same time increase Order operation is difficult, the procedures are complicated, and the delivery time is long.

(2) Compare / confirm prices

Buyers have the right to place orders / contracts with the most appropriately priced suppliers in the supplier group to safeguard the best interests of the business.

(3) Confirm the standard and quantity of required materials

9. How to track purchase contracts?

(1) Tracking process files

A. For the procurement of any outsourced parts (materials that need to be processed by the supplier), the order personnel should track the process documents provided to the supplier.

B. If it is found that the supplier does not have relevant process documents, or the process documents have quality and delivery issues, the supplier should be promptly reminded to modify.

C. Suppliers and time goods are required to pay compensation in accordance with the terms of the contract if they cannot guarantee the quality, quantity and punctual supply.

(2) Tracking the supplier’s raw materials

After receiving the contract, some suppliers think that they are “done”. When necessary, they must remind the suppliers to prepare raw materials in a timely manner, especially for those with poor reputation / less cooperation.

(3) Tracking process

For one-time / large-expense project procurement, equipment procurement, construction procurement, etc., in order to ensure delivery time, quality, procurement personnel need to monitor the processing process, and even participate in the supervision of the processing process.

(4) Track assembly and test

Final assembly and testing is an important part of product production, and it is required that purchasers have a good professional background and industry work experience.

(5) Track packaging and storage

Purchasing staff can learn the storage information of materials by telephone. For important materials, the purchaser is best to visit the supplier site.

For some urgent materials, the procurement personnel must fully track; for suppliers who have a stable and long-term supply, they can consider eliminating the contract tracking link.

10. What are the commonly used contract terms?

A formal sales contract includes the following:

(1) Name

(2) Number

(3) Date of signing

(4) Place of signing

(5) Name of buyer and seller

(6) Address

(7) Preamble to the contract

(8) Product name

(9) Quality specifications

(10) Quantity

(11) Packaging

(12) Unit price and total price

(13) Delivery period

(14) Place of arrival

(15) Payment

(16) Insurance

(17) Commodity inspection

(18) Arbitration

(19) Force Majeure

(20) Number of contracts

(21) Use of language and its effectiveness

(22) Annex

(23) Effective date of the contract

(24) Signature and seal of both parties

The following are optional parts

(1) Value preservation clause

(2) Price adjustment clause

(3) Error range clause

(4) Terms applicable to law

On November 28, 2019, the CPC Central Committee and the State Council issued the Guiding Opinions on Promoting the Development of High-Quality Trade. The “Opinions” requires that by 2022, the trade structure will be further optimized, the trade benefits will be significantly improved, the trade strength will be further enhanced, and an indicator, policy, statistics and performance evaluation system for high-quality trade development will be established. The “Opinions” proposes to strengthen international cooperation in service trade and build a “Chinese service” national brand.

The “Opinions” requires the establishment of an open, collaborative and efficient common technology research and development platform to strengthen the supporting role of manufacturing innovation in trade. Promote the organic integration of the Internet, the Internet of Things, big data, artificial intelligence, blockchain and trade, and accelerate the cultivation of new kinetic energy. Strengthen original innovation and integrated innovation. Make full use of multilateral and bilateral cooperation mechanisms to strengthen technical exchanges and cooperation. Efforts will be made to expand foreign licensing of intellectual property. Actively integrated into the global innovation network.

In addition, the “Opinions” also pointed out that the role of market mechanisms should be brought into play to promote the interaction between trade and industry and promote the process of industrial internationalization. Accelerate the development and cultivation of emerging industries and promote breakthroughs in key areas. Optimize and upgrade traditional industries and increase competitiveness. Accelerate the development of modern service industries, especially productive services, and promote the deep integration of advanced manufacturing and modern service industries. Speed ??up the construction of modern agriculture. Cultivate advanced manufacturing clusters with global influence and competitiveness.

So, what is the current situation of China’s foreign trade development?

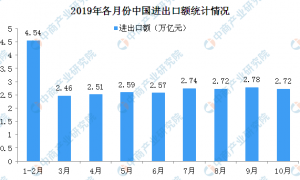

In the past two years, the outbreak of the Sino-US trade war has had many impacts on China’s trade industry. In the face of a complex and severe foreign trade development environment, China resolutely implements the decision-making and deployment of the Party Central Committee and the State Council, does a good job of “stabilizing foreign trade,” and vigorously promotes the “five “Optimization”, continued to promote the “three constructions” of foreign trade transformation and upgrading bases, international marketing networks and trade promotion platforms, actively promoted the development of high-quality trade, and achieved positive results in various tasks. According to the latest data from the Ministry of Commerce, from January to October, China’s foreign trade development steadily improved.

1. The scale remains stable.

From January to October 2019, China’s total import and export volume was 25.63 trillion yuan, an increase of 2.4%. Among them, exports were 13.99 trillion yuan, an increase of 4.9%; imports were 11.64 trillion yuan, a slight decrease of 0.4%; the trade surplus was 2.35 trillion yuan, an increase of 42.3%. From an international comparison, according to the latest data from the WTO, the growth rate of China ’s imports and exports in the first eight months was higher than the average growth rate of major global economies.

2. The structure is continuously optimized.

The international market layout has been optimized. Imports and exports from countries along the “Belt and Road” have grown by 9.4%, accounting for an increase of 4.1 percentage points to 29.1% in 2013. The domestic regional layout is optimized. The exports of the central and western regions increased by 13.8%, which was 8.9 percentage points higher than the overall exports, accounting for an increase of 1.4 percentage points from the same period last year to 18.1%. The product structure has been continuously optimized, and the export ratio of mechanical and electrical products has reached 58.3%. Among them, exports of high-quality, high-tech, high-value-added products such as integrated circuits, photovoltaics, excavators, and medical equipment have maintained rapid growth. The export of seven major labor-intensive products increased by 6.1%. Among them, toys, textiles and footwear increased by 32.2%, 5.5% and 5.4% respectively. The operating entities continued to optimize. The export of private enterprises increased by 12.8%, accounting for an increase of 3.6 percentage points to 51.3%, driving the export growth by 6.2 percentage points. The trade structure was further optimized. General trade exports increased by 8.5%, accounting for an increase of 1.9% to 58.2% over the same period last year, and contributed 97.6% to export growth.

3. Speeding up power conversion.

Deeply cultivate new trade formats and new models, solidly promote the construction of cross-border e-commerce comprehensive test zones and market procurement and trade pilots, introduce related taxation and other supportive policies, and vigorously develop new models of new business formats such as cross-border e-commerce and market procurement Faster than the national average. Speed up the export of second-hand cars, further simplify the work flow of transfer of vehicles in different places, permit application, and customs clearance, and create a convenient environment for the export of second-hand cars. Vigorously promote the bonded trade maintenance project of processing trade on a trial basis.

At present, a new round of reform and opening-up has injected new vitality into the development of foreign trade. The Second China International Import Expo was successfully held. The simplified administration and decentralization were further promoted. The policy bonus was gradually released. The business environment continued to improve, and corporate policies gained a sense of gain. According to the World Bank’s “Business Environment Report 2020”, China’s business environment ranking jumped from 15th to 31st. The questionnaire survey shows that more than 70% of enterprises are generally satisfied with the implementation of the stable foreign trade policy. In the next step, guided by Xi Jinping’s ideology of socialism with Chinese characteristics in the new era, we will adhere to the general tone of progress while maintaining stability, make greater efforts to stabilize expectations, stabilize enterprises, and promote high-quality trade development.

Fabric, as the name implies, is the material used to make clothing. As one of the three elements of clothing, fabric can not only interpret the style and characteristics of clothing, but also directly affect the color of clothing, modeling performance effect. Good fabrics play an absolutely critical role in garment production, so the fabric needs to be inspected and tested.

ONE. fabric inspection items and basic quality requirements

Inspection items:

The appearance, weight, density, feel, pattern, color, width, piece length, skew or arc of weft shall be inspected.

Basic quality requirements:

1. The fabric and lining of all kinds of finished products shall not be torn, damaged, broken or seriously defective, such as coarse yarn, which may affect the wearing effect.

Yarn defects, knots, variegated yarns and fabric edges/pinholes;

2. The texture of various fabrics includes composition, feel, gloss, fabric structure, pattern and printing position, size,

The color and density shall be consistent with the sample requirements;

3. Oil, rust, color, water marking, offset printing, scratch printing and other stains are not allowed in all kinds of fabrics and materials.

4. The surface of knitted fabrics shall not be uneven, and the surface shall not have yarn joints;

TWO, fabric inspection procedures

1. Determine the inspection quantity: normally sample size is applied by international inspection standard Default Level II, or required by the customer;

2. Choose the inspection package number or volume number: the fabric inspector can randomly pick out the fabric that needs to be inspected according to the fabric factory’s fine size list

Cover all colors. The inspection quantity of each color is determined according to the proportion of each color in the batch of fabric;

3. Check the fabric quantity: check whether the actual quantity is consistent with the supplier’s fine size order, packing code order and marking code of cloth volume

4. Check the color and feel of the fabric: check whether the color and feel of the fabric are the same as the color and quality samples of the fabric confirmed by the customer;

5. Check the fabric width: measure the actual width of the fabric head, middle and tail, and the fabric width should meet the order requirements;

6. Check the color check: check whether there is any deviation between the two sides and the cloth in the middle. Fabric can not have before and after chromatic aberration, left and right

Chromatic aberration and color flower. Check whether the color and feel of the fabric are the same as the color and quality samples of the fabric confirmed by the customer; color

The discrepancy shall not be less than level 4 or the standard required by the customer, and the discrepancy shall be more than level 4;

7. Check the defects on the fabric inspection machine. The speed of the fabric should be suitable. Improper speed will affect the accuracy of cloth inspection. When making defect inspection, marks should only be deducted for visible defects that affect garment processing and affect appearance. Make records while checking.

8. When defects are found during fabric surface inspection, use the color line to make an obvious mark, so that cutting and paving materials can be found at any time. If this batch of fabric is not qualified, it needs to be returned. It is also convenient to explain the defect status and reason of return to the fabric factory, and record the deduction points.

9. Count the number of unqualified cloth rolls and count the number of defects to determine whether they are qualified.

China’s manufacturing industry has been very developed and is a big exporter of clothing, shoes and hats. However, textile is an intensive industry whose development is influenced by many aspects, such as labor cost, raw material supply, land resources, environmental protection and sales market.

Early at the center of the global footwear in European countries such as Italy, Spain and Portugal, began to shift to the relatively low cost in the 60 s of Japan, Hong Kong, China and South Korea and other countries and regions, in the late 1980 s and early ’90 s, and moved to land labor cost more cheaply, more rich industrial resources, investment environment more perfect coastal areas of China.

After entering WTO, China’s shoe industry entered the golden age of development, shoe output and export grow ceaselessly, become world shoe center. Since 2011, the world economic recovery is slow, China’s shoe industry began a difficult period of transformation and adjustment.

In recent years, although China’s share of world shoe production has declined, it remains the world’s largest shoe-producing country. In 2016, China produced 13.11 billion pairs of shoes, accounting for 57.0 percent of the world’s total. In 2017, China produced 12.62 billion pairs of shoes.

Rising labor costs, raw materials and currency fluctuations have prompted shoe companies to relocate to southeast Asia in recent years. With the full launch of china-asean free trade area, the shoe industry in Vietnam, India, Pakistan and other places develops rapidly, which poses a great potential threat to China’s shoe industry.

In recent years, China’s shoe export situation is relatively severe. On the other hand, the European Union, the United States and other countries set higher tariff barriers to Chinese shoes, which makes the export competitiveness of shoes from southeast Asian countries lower.

According to the data, China’s shoe exports reversed the downward trend in 2017, with both the quantity and the amount of exports increasing. The annual export volume reached 9.643 billion pairs, up by 3.77% over the previous year. Exports reached $45.66 billion, up 1.74% year on year.

Vietnam is China’s biggest rival among southeast Asian nations. After the 2008 global financial crisis, Vietnam gradually diverted the global textile, clothing and footwear orders undertaken by China due to its labor cost, raw material price and other advantages, and even attracted some of China’s high-quality footwear, textile and apparel enterprises’ production capacity.

In 2016, Vietnam produced a total of 1.24 billion pairs of various kinds of shoes, of which exports accounted for about 1.1 billion pairs, with the export volume reaching 7.8 billion us dollars, ranking second in the world in terms of both quantity and amount of exports, second only to China, and far ahead of Indonesia (2.6 billion us dollars), which ranked third.

This shows, Vietnam’s shoe production, export ability is in a rising stage. Some analysis points out that Vietnam’s shoe industry, textile and garment industry, due to labor costs, enjoy preferential treatment in the international market and other advantages, there is still a lot of room for growth in the international market. This also means that China’s shoe exports are facing increasing competition from Vietnam, and the latter’s labor costs and other advantages will continue to be prominent in the future.

Below are some common checking list for Disposable medical cap quality control inspection service:

1,size and weight test

2,appearance check

3,marking & labels check

4,pull test

5,function test

6,packing check

7,rubbing test

8,carton drop test

9,product gsm check

10,color difference check