nut

Hex Cap Nuts

Hex Serrated Nuts

Hex Flange Nuts

Hex Coupling Nuts(High Nuts)

Round Nuts

Square Nuts

Pipe Nuts

Wheel Nuts

Wing Nuts

U Nuts

T Nuts

Eye Nuts

Kep Nuts

Clinch Nuts

Weld Nuts

Heigh Strength Nuts

Structural Nuts

Stainless Steel Nuts

Brass Nuts

Aluminum Nuts

Alloy Steel Nuts

Heavy Duty Wheel Hub Nuts

Acorn Cap Nuts

All-Metal Prevailing Torque Type Nuts

Anchor Nuts

Big Size Nuts

Closed End Acorn Nuts

Conical Washer Nuts

Hex Head Machine Bolts

Hex Lag Bolts

Square Head Bolts

Carriage Bolts

Eye Bolts

Hex Socket Cap Screws

Set Screws

Stud Bolts

Screw Studs

Wheel Bolts

Wing Screws

Self Tapping Screws

hread Cutting Screws

elf Drilling Screws

Drive Screws

Machine Screws

Wood Screws

Furniture Screws

Chipboard Screws

Drywall Screws

Foundation Bolts

U Bolts

Hook Bolts

Toggle Bolts

Flange Bolts

Track Bolts

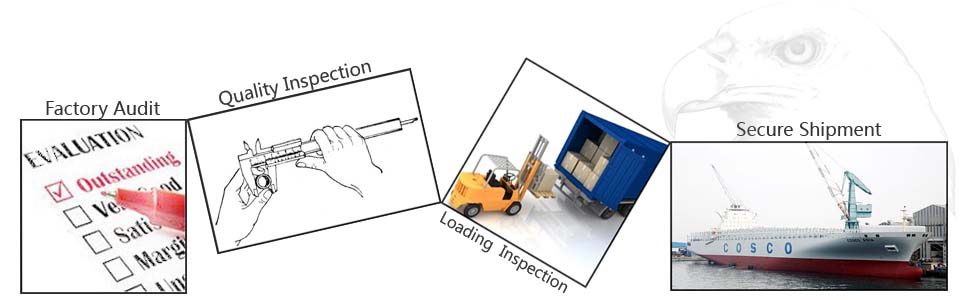

Some common factors for screws and nuts quality control:

1.Appearance inspection: under the condition of appropriate illumination, open hole distance 30 cm to check by visual inspection;

2.Dimensional inspection: use vernier caliper to measure its structure size; the tolerance should be within 0.02 mm.

3.Surface electroplating: require surface electroplating is good, no oxidation, scratches,and other bad plating phenomenon.

4.Assembly effect: Select standard screw head, use electricity, wind batch screw hole in plastic or play 5 times in a row, on the standard matching nut screw groove no killing, screw not fracture, sliding wire nut: with standard screw sleeve, not smooth silk or screwing in difficulties

5.Oxidation resistance: steep In saline s after 2 hours to dry after 24 hours to see if the screw surface will have oxidation, rust

6.Product packaging requirements products piled up neat and moisture protection.