Different kinds of vacuum cleaner quality inspection:

Handy & Stick Vacuum Cleaner

Multi Cyclone Vacuum Cleaner

Single Cyclonic Vacuum Cleaners

Double Cyclonic Vacuum Cleaner

Wet & Dry Vacuum Cleaner

Water Filter Vacuum Cleaner

Commercial Vacuum Cleaner

Bagged Vacuum Cleaner

Backpack Vacuum

Car Vacuum Cleaner

Vacuum Cleaner accessories

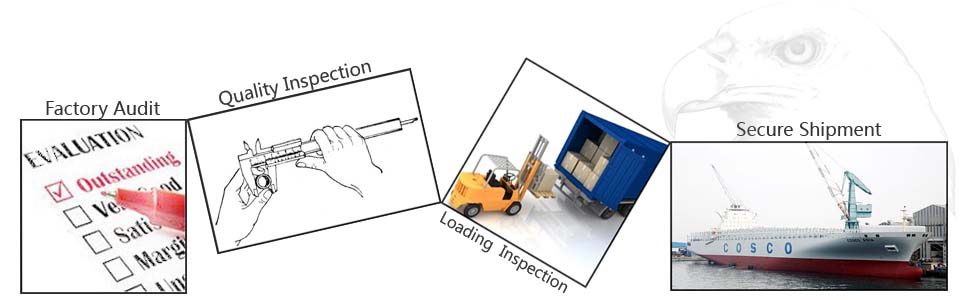

1 Quantity, Production and Shipment Status

1 Quantity, Production and Shipment Status

2 Packing Size and Shipping Marks

3 Barcode and Labeling

4 Design, Version, Material and Colors

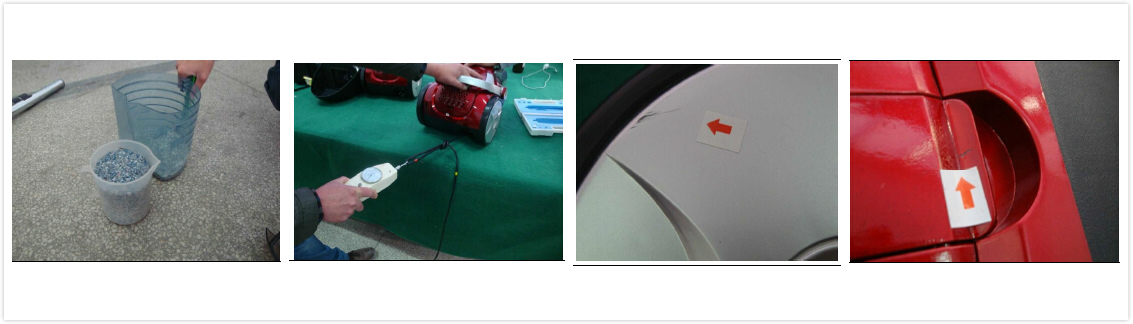

5 Workmanship Defects:

The coating was peel off on surface of product

Scratch mark on surface of product

Dirt mark on the surface of product

Poor coating on the surface of product

6 Function Tests:

Silk screen printing adhesion test

Rating label rubbing check with alcohol

Hi-pot test (4000V, 2s, 5mA)

Basic function test

Assembly test

Using function check

Power consumption check (230V, 50Hz)

Product endurance test (4 hours)

Power cord anchorage test (100N 25times)

Power cord length check

Internal workmanship check

Low voltage starting test (85% of rating power)

Low noise test (<76dB)

Vacuum degree test

Volume of container

7 Critical Components Against CDF:

Power Plug

Power cord

Switch

Capacitor

Internal wiring