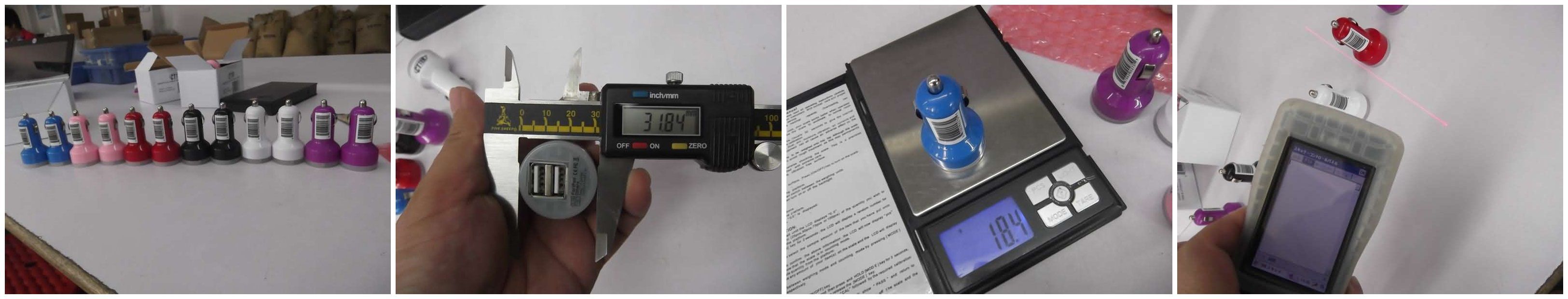

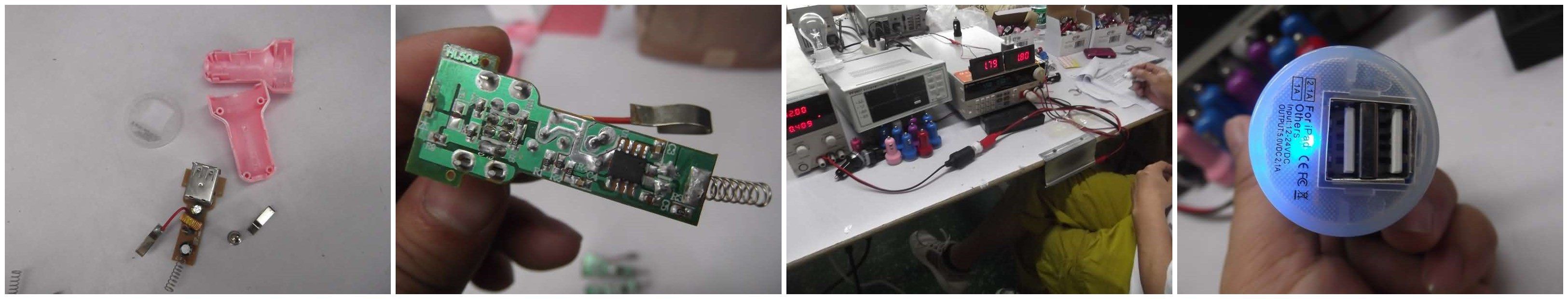

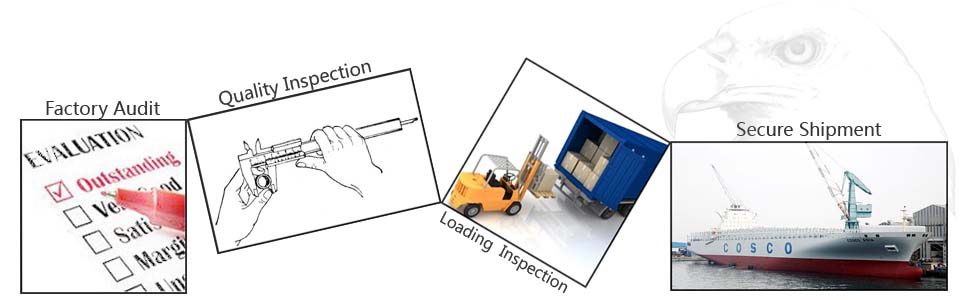

First Article Inspection is one of the primary methods for the "inspection and testing of vendor components."The testing of a pre-production samples is considered essential in the process of approving an order or contract; the first article inspection should determine if the product meets acceptance requirements and quality control requirements. Customers who perform such inspections are recommended to identify this in the contract, and to use specific forms to document the results.

The purpose of the First Article Inspection is to give objective evidence that all engineering, design and specification requirements are correctly understood, accounted for, verified, and recorded. The purpose of this standard is to provide a consistent documentation requirement for aerospace components FAI.

FIRST ARTICLE INSPECTION (FAI): A complete, independent, and documented physical and functional inspection process to verify that prescribed production methods have produced an acceptable item as specified by engineering drawings, planning, purchase order, engineering specifications, and/or other applicable design documents.