2019 is a year of “turbulence” in the global industry chain. Not only is this happening between China and the United States, but even Japan and South Korea have erupted in such tit-for-tat games.

On May 15, the U.S. Department of Commerce issued a “ban” on Huawei, placing Huawei and its 70 subsidiaries on the “physical control list”, so that US companies must obtain permission before selling products to these companies. Although the official website of the U.S. Department of Commerce announced on the 20th that it will give Huawei and its partners a 90-day temporary license. According to media reports in August, the U.S. has extended the temporary license to Huawei again. The meaning of “untie”.

On July 1, Japan announced that it would increase its efforts to restrict the export of three core cutting-edge materials to South Korea, and began to officially restrict the export of related products to South Korea on the 4th. This will undoubtedly cause a “fatal” blow to the semiconductor industry in China and South Korea. Because there is a weakness for industries such as semiconductors that have a mature and strict global division of labor system, that is, raw materials are extremely dependent on the international market, especially the supply of the United States and Japan.

Now, self-help is imminent. On the one hand, localization is required, and on the other hand, no single material or a few key materials are held in the hands of certain countries or manufacturers, so that the risk of such “trade shocks” can be minimized. Therefore, from the perspective of the development of the trend, the global stable and one-way industrial chain over the past few decades is being broken.

Changing global supply chain management

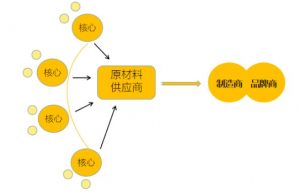

With the changes of the globalized industrial chain and the advent of the Internet, the possible links of a commodity supply chain include local factory production, production at multiple factories overseas, and finally procurement in multiple countries around the world. This requires that New global supply chain management service capabilities. In other words, in the globalized industrial chain, in the future, a core component will include multiple core enterprises, and may be distributed in multiple countries. At the same time, these core companies need to purchase raw materials in multiple countries around the world. This can also be seen as a reflection of the evolution and upgrade of supply chain management from line to face.

In the traditional “chain” supply chain management, multinational companies have a large number of participants, each link is too trivial and scattered, serious faults, and the degree of visualization of the entire chain is very low. Operating costs increase.According to the survey, there are still a considerable number of multinational companies who do not know who their suppliers are at all levels, where the source and downstream are. This brings the risk that it is difficult for companies to monitor the operation and implementation of different suppliers in their supply chain. . Therefore, with the transformation and development of the manufacturing industry, at the domestic and global scale, breaking the information silos and achieving interconnection between manufacturing enterprises will become urgent problems to be solved.

On January 29, 2019, Punta, which received a round of 2.4 billion yuan (the largest single financing in the supply chain logistics field), emphasized that “Juda will continue to increase investment in globalization and other aspects. At the same time, it is officially proposed that Efforts to create a new layout of Manufacturing Digital SCM (referred to as MDS, manufacturing digital supply chain). Through the digitalization-driven intelligent manufacturing collaborative supply chain solution, help companies shorten the supply chain, reduce the total supply chain cost, and change the supply of traditional manufacturing The chain has shifted from a single-line link for companies on a single chain to a networked, multi-layered, all-round link. ”

Aiming at the two characteristics of “digital drive” and “cooperative sharing”, Punctual’s approach is to use the same platform to connect multiple participants who are active in different industries on the B2B supply chain. Through AI, big data, IoT and other new types Technology provides them with visualization, collaboration, and digitization, enabling seamless linking and dynamic visualization of collaboration and information transfer between different roles, reducing inventory and reducing volatility. In the future, we can see that the management of a manufacturing supply chain will change from a pure manufacturing supply chain to a digital supply chain in the manufacturing industry to a digital supply chain in the future. The scope of services is constantly expanding, and the technology content Is also constantly improving.

Attacks by Chinese supply chain companies

In the globalized industrial system, there have been three generations in history under the domination of the United States. From Germany and Japan to Southeast Asian countries represented by the four Asian dragons, and then China has become the third-generation producer in the globalized division of labor system led by the United States. Over the past two decades, China has mainly exported low-value-added personal consumer goods to the world. In the future, it will focus on breaking through high-end manufacturing and high-tech industries. Intelligent manufacturing has become a new direction for industrial upgrading.

In this context, we see that the three major economies of the United States, Germany, and Japan have spawned world-class global supply chain giants such as UPS, FedEx, and DHL. As the second largest economy in the world, driven by the new industrial era and digital technology, it is expected that China will have more than one world-class global supply chain giant in the future.

A new global supply chain is inseparable from a global network. For large B2B manufacturing companies, the market for supply chain logistics is global. From the global procurement of raw materials to the external output after the finished products are produced in factories in multiple countries, in every link of the supply chain, the support and coordination of global network resources are inseparable. Network coverage not only determines the volume and revenue, but also has a significant impact on service coverage and timeliness.

With the in-depth development of economic globalization, the highly integrated industrial chain and supply chain system have connected the “backbone” of the world economy. It is precisely because of this that the global supply chain system is greatly affected by policies and the situation. The prolonged Sino-US trade frictions also allow The global supply chain landscape is changing. In this regard, on time, the full-time supply chain service capabilities accumulated by large-scale multinational corporations on time have been significantly released, and with its 155 bases established in the United States, Japan, South Korea, Vietnam, India, Southeast Asia, Europe, and other countries, Global network resources and strong resource integration capabilities, it can respond to the constantly dynamic reorganization of the global supply chain network with flexible supply chain full-link management.

Take Vietnam as an example. Due to its advantageous geographical location and demographic dividend, it has attracted world-class companies such as Intel, Samsung, Coca-Cola, Pepsi, P & G, Nestle and other factories in Vietnam. It is precisely because of the blessings of more and more world-class manufacturers that the demand for professional integrated international logistics services in Vietnam will increase in the future. Moreover, the service is not only a simple transportation and warehouse declaration, but also extends to global supply chain management. No doubt Vietnam will become one of the very important nodes in the global supply chain in the future.

It is also because of Vietnam ’s unique geographical advantage that Puntastar has already carried out a strategic layout in Vietnam. With Vietnam as a tie, Puntastar has assisted manufacturing companies to open the Belt and Road corridor from Vietnam across China to Europe and south from China via Vietnam Comprehensive services for the supply chain foreign trade in the ASEAN Free Trade Area of Southeast Asia, and radiate the land, sea and air transportation network to the United States, Mexico, India and other countries. While providing supply chain logistics for these multinational manufacturing enterprises, reverse logistics and integrated customs services are also Vietnam’s most prominent advantage. Therefore, Vietnam punctuality is “the best local supply chain logistics company in China”.

Different from traditional logistics companies, Juntime is based on building a global network base. It has practical experience in integrating from the manufacturing chain to the distribution chain. It is one of the few end-to-end supply chain management service enterprises with a global network layout. Customers provide full-scale supply chain integration solutions from raw material procurement to factory manufacturing to the end-to-end consumer link (C2M2C).

On time, Junda played the role of coordination, coordination and operation in Sharp’s global supply chain management. It participated in Sharp’s supply chain planning, coordinated with upstream and downstream participants in the supply chain, organized various resources, and promoted the entire supply. The efficient operation of each link of the chain system is reflected in logistics services. It integrates various types of logistics service providers to realize the operation and management of procurement / entry, on-site, sales and after-sales logistics.

In terms of international air and sea freight, SJL has conducted global bidding through the combination of goods and goods with internationally renowned companies such as Foxconn and Sharp. The combination of resources and scheduling has helped Sharp save nearly 30% of international air and sea freight each year. In addition, in the entire project of Sharp, for domestic logistics in Japan, SJL has also integrated various warehouses and optimized store distribution routes to help Sharp reduce costs and increase efficiency. ”

SJL also launched a transport collaboration platform system for Sharp this year. The next step is to connect multiple participants from different industries active in the B2B supply chain to digitize and visualize the entire flow of goods in transit. Because for a sales manufacturer with multiple production bases overseas, this is a new driving force for the upgrading and transformation of the supply chain of manufacturing enterprises. For example, grasp the quantity being produced in the factory, the quantity of finished products to be shipped, the quantity of goods already on board, the quantity of goods ready for customs clearance, the quantity of goods already in the warehouse, etc. In this way, Sharp can control the overall inventory situation in real time, and then maximize the efficiency by deploying other functional departments. This is a function that SJL will implement in the future.

In Sharp’s entire project, it involves services such as cross-border transportation, VMI warehouse management, supply chain management (planning, procurement, production, sales, etc.), customs services, and finance. The core of the future is to use data to connect from raw material production and manufacturing to storage management, to goods transportation, and after-sales, including processing, finance and other services, to realize the digitization and visualization of the entire process.

From the perspective of SJL’s development, the core of the end-to-end service to complete the global supply chain management lies in the global resource capabilities (warehouse trucks, etc.) and data-based collaborative platforms.

In general, the global industry chain is changing, and the accompanying changes in the supply chain platform. To achieve the upgrade of cost, efficiency, and experience, it is definitely not the current logistics system, but is driven by technology and penetrates into the supply chain. Upstream and downstream collaboration, global platform.