reinforced bar,rebar,twisted steel

Carbon Structural Steel Plate

Low alloy hi-strength structural steel plate

Quality Carbon structural steel plate

Normal strength hull structural steel Plate

High strength hull structural steel plate

Low Carbon Hot-rolled wire

Coil for wire production

Quality hot-rolled carbon steel coil

Hot-rolled coil for prestressed wire

Coil for Welding

Deformed wire coil

Rebar

Regular carbon plain bar

Quality carbon structural plain bar

Alloyed stural plain bar

plain bor

Tube Billet

Hot-rolled strip

Structural Steel

Die Steel Forgings

Stainless steel

Bearing Steel

Wire for musical instrument

Flat spring steel

Carbon Steel wire for spring making

Quality Carbon Structural Steel wire

Carbon Steel Wire for special usage

Profiled wire

Alloyed spring steel wire

Quality Structural Steel

Stainless Steel Wire

Wire for needle making of sewing machine

Strip for quality Tape Making

Thermal treatment spring steel strip

alloy tool steel

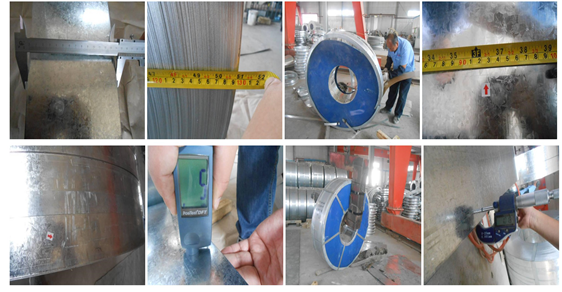

1.Check the material’s specification according to the purchase order

2.Use appropriate measuring tools to measure each project to detection of different parts of not less than three times (such as measuring the diameter of the round steel, it should be in every round steel ends and the middle part of measurement confirmation)

3.Hardness inspection: the inspection according to material of model checking is related to the effective data files, confirm what is the hardness, using hardness tester for testing, sampling of the surface of the material requirements must conform to the requirements of the relevant durometer measurement.

4.Appearance inspection: mainly on the material appearance shape, inspection of surface defect: For appearance’s defects, can use visual inspection, for High Precision Process, it is not easy to detect the shape of the demand by visual inspection , it needs appropriate measuring tool to measure.

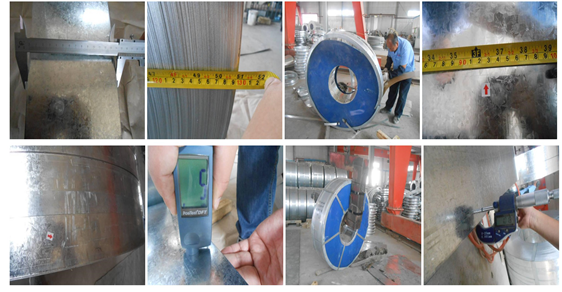

5.Common defects following:

1) Ovality: round section of metal materials, there is phenomena of that different diameter on the same cross section of different directions

2) Bending: bending is rolled material.In the length or width is not flat, is in the shape of the curve

3) Reverse: strip rolling material along the longitudinal axis twisted into a spiral

4) Sickle bending/profile: refers to the metal plate, belt and close to the rectangular section bar section along the length of the narrow (surface) side bending, angled a concave curve, the other side are angled to the convex curve

5) Ladle curvature: refers to the board or the length and width of wave phenomena of ups and downs in at the same time;

6) Surface crack: refers to the metal object surface crack

7) Uneven: steel plate, steel strip and steel pipe ( wall thickness is Uneven)

8) Ears: because of improper roll with the bumps along the rolling direction outspread

9) Rolling skin: Refers to the uneven distribution in the material surface tongue shaped, nails or designed in flakes

10) Fold:It is the metal in the process of hot rolling or forging forming of a kind of surface defect, surface or double metal layers, with each other in a straight line or curve.