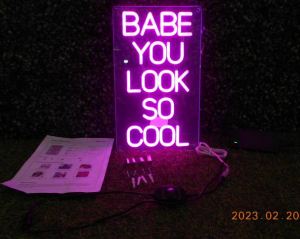

1.Barcode scan test

1.Barcode scan test

2.3M tape test

3.Rub test

4.Aging test

5.Assembly test

6.Dimmer function test

7.Dimmer knob fatigue test

8.Power-on lighting test

作者: admink

Stand Fan Final Inspection

1.Hi-pot test

2.Ground continuity test

3.Fatigue test

4.Internal workmanship check

5.Speed test

6.Barcode Scan test

7.Power consumption test

8.Stability test

9.Adhesion test

10.Remote test

11.Product endurance test for about 5 hour

Net Quality Check

1.Appearance check

1.Appearance check

2.Barcode Scan

3.Drop carton test

4.Smell test

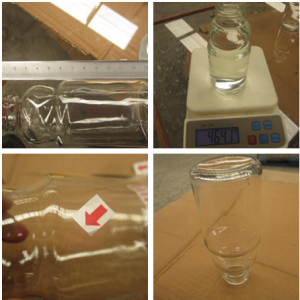

Glass Quality Control Inspection Service

1.Pour Water Test

2.Hot water test

3.Product capacity test

4.Product transparency test

5.Product balance test

6.Cleanliness test

7.3M tape test

8.Rub test

Barriers Quality Check Service

1.Appearance

1.Appearance

2.Quantity check

3.Material check

4.Function test

5.Pull test

6.Brute force test

7.GSM-300G

8.Consistency test

9.Assembly test

Keg Washing Machine Pre-shipment inspection service in jining

1.Logo/Printing 3M Tape test

1.Logo/Printing 3M Tape test

2.Basic function check (Functions on product specification work )

3.Barcode Scan

4.Rubbing test

5.304 stainless steel check

6.Appearance

7.Measurement of product

8.Completeness of the body

9.Printing quality check

Glass Cup Quality Inspection

1.Logo/Printing 3M Tape test

1.Logo/Printing 3M Tape test

2.Water Leakage test

3.Volume test

4.High temperature test

5.Balance test

6.Hot and cold shock test

7.Rocking on flatness surface

8.Basic function check (Functions on product specification work )

9.Pour water function test

10.Gap check <0.5mm Check

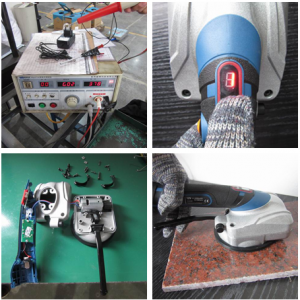

Tile tiling Quality Control Inspection Service

1.Hi-pot check(G-II)

2.Basic function check(G-II)

3.Accessories check(G-II)

4.Smell check(G-II)

5.Full function check(S-3)

6.Internal check

7.Charging time test

8.Discharging time test(no load)

9.No-load speed test

10.Adaptor output current voltage test

11.Power test

12.Noise test

13.Rub test

14.Tape test

15.Battery voltage check after fully charged

16.Application check

17.Barcode scan test

18.Carton drop test

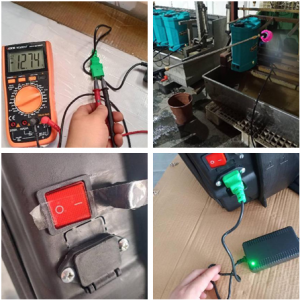

Electric Sprayer Quality Control

1.Logo/Printing 3M Tape test

1.Logo/Printing 3M Tape test

2.Basic function check (Functions on product specification work )

3.Barcode Scan

4.Battery and charging test

5.Capacity check

6.Water spray test

7.Shoulder straps and cap load test

8.Noise level check

9.Residual liquid check

Coffee Cup Full Quality Check

1.Logo/Printing 3M Tape test

1.Logo/Printing 3M Tape test

2.Capacity test

3.Flatness check

4.Washing test

5.Microwave test

6.Humidity check

7.Cup flatness check

8.Cup hot water washing test